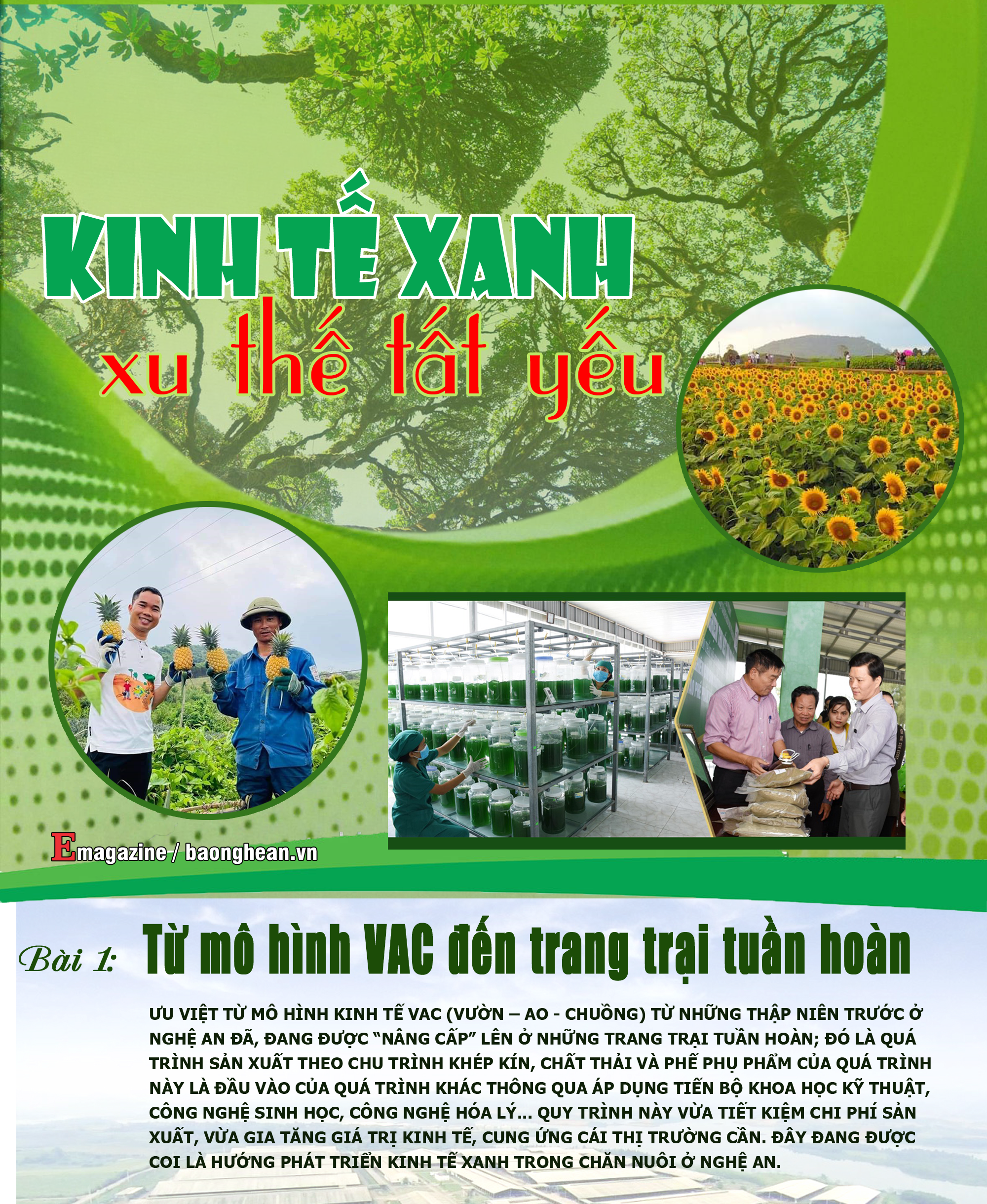

The garden, pond, and barn (VAC) economic model has been widely applied in Vietnam since the past decades and is considered the simplest form of circular agriculture. In which, the garden is the activity of growing crops, the pond is the activity of raising aquatic products, and the barn is the activity of raising livestock and poultry... in households, farms, and ranches. VAC has demonstrated the ability to create a new agricultural ecosystem, integrated production, linking cultivation with livestock, limiting waste, following nature, and proactively providing on-site supplies to people.

From the VAC model, “improved VAC” models have emerged such as Garden – Pond – Barn – Biogas (VACB); Garden – Pond – Barn – Forest (VACR) is a model combining VAC with forestry activities in mountainous provinces; Garden – Pond – Lake (VAH) is a sand farm model in the Central provinces… which not only helps reduce greenhouse gas emissions but also brings good and stable income to people.

In particular, VACB is a solution to overcome the irrationality in waste management, rationally using agricultural by-products as fertilizer to restore soil fertility. Safely treating animal waste, creating renewable energy such as fuel for daily life, fighting environmental pollution and contributing to reducing emissions, reducing the greenhouse effect causing climate change...

In Nghe An province, there are currently nearly 800,000 buffaloes and cows, nearly 1 million pigs and 34 million poultry. If farmers only care about the main products and ignore by-products, the amount of emissions will lead to pollution and affect the living environment. Realizing that, not only large farms but also many households and households in the province have developed circular livestock models, such as: VACB; raising cows - growing fruit trees; raising cows - earthworms - growing grass/corn/fruit trees; raising poultry - fish...

In fact, circular agricultural production is increasingly proving to be a suitable direction for sustainable agricultural and rural development. Currently, in Nghe An, the biogas pit movement is quite popular in many districts such as Nam Dan, Thanh Chuong, Hung Nguyen, Tan Ky... with hundreds of effective models, overcoming the previous polluted livestock farming situation; at the same time creating a source of gas, organic fertilizer, and safe wastewater for irrigation to serve cultivation.

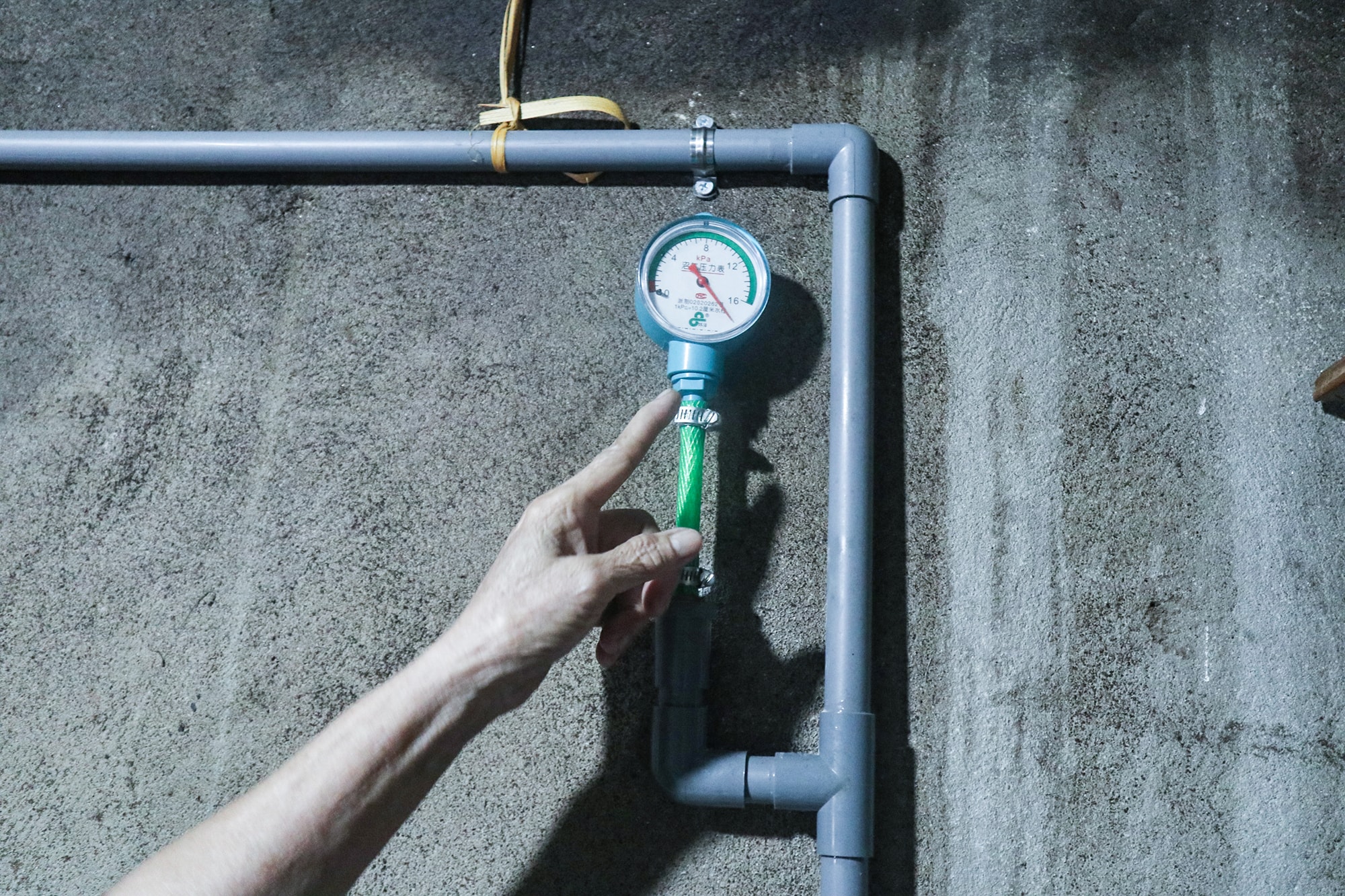

Ms. Hoang Thi Thuy's family (Xuan Thanh hamlet, Phong Thinh commune, Thanh Chuong district) makes rice paper. On days when there is no sun to dry the rice paper, Ms. Thuy has to use a gas stove to dry and press the rice paper, consuming a lot of gas. Ms. Thuy said: "Every month, about 1.5-2 industrial gas cylinders are used, about 1 million VND. That's not to mention cooking rice and boiling water, which uses electricity. That's quite a large expense"... By February 2023, Ms. Thuy's family had built a biogas tank to use animal waste as fuel. Accordingly, with 15 pigs and 1 buffalo of the family, the amount of waste discharged is very large, only used to fertilize plants and fields, but not all, must be discharged directly into the garden, so it is very polluted. “Farmers, without livestock, will not have “money out, money in”, and livestock farming makes waste treatment a very difficult problem. Since building a 10m3 biogas tank, all animal waste has been processed into gas, and the residue has been fermented to make organic fertilizer. The clean, odorless wastewater is a source of water for plants. The pollution problem has been completely solved, and there is still excess gas for baking and cooking,” said Ms. Thuy.

From the effectiveness of her family, Ms. Thuy and her siblings contributed money to build a biogas tank for her parents. “My grandparents raised 30 pigs, and the waste discharged daily was large, so the neighbors complained and sometimes even had conflicts. When they saw the “double” effectiveness of using a livestock waste treatment tank, my grandparents installed a biogas tank, and everything was basically resolved,” Ms. Thuy shared.

For the family of Ms. Hoang Thi Mao in Lien Chung hamlet (Phong Thinh commune, Thanh Chuong district), located on a steep hill, the area is quite limited, the row of livestock barns is adjacent to the house and the well, so raising livestock faces many difficulties. When there was a project on biogas tanks, her family registered to build immediately. The total cost to build a biogas tank, gas pipeline, kitchen... was about 10 million VND. "The initial capital may be a bit much, but it almost completely solves pollution in livestock farming, and there is a source of excess fuel for cooking, my family has saved 500,000 - 700,000 VND per month," Ms. Mao said.

One of the pioneering families in building biogas tanks in Thanh Hoa commune (Thanh Chuong) is Mr. Nguyen Trong Dung's family (Dong Hoa hamlet). Their conditions are purely agricultural, so to ensure economic stability, his family must choose household livestock farming as the main source of income. The family has many people, high fuel demand, and a lot of livestock, so Mr. Dung had to build a biogas tank to solve environmental problems. In addition to thoroughly treating the stench and keeping the environment clean, for the past two years, Mr. Dung's family has not had to buy cooking gas, saving 5-7 million VND per year on gas.

In the process of building new rural areas, one of the difficult criteria in localities is the environmental criteria. However, the biogas pit model to treat livestock waste into clean energy is bringing dual benefits. Mr. Tran Van Ky - Chairman of the Farmers' Association of Phong Thinh Commune (Thanh Chuong), said: "Previously, environmental pollution in livestock farming in residential areas was always a "hot" issue, and disunity from the problem of waste discharge into the environment was also here. In the past two years, in the commune, there have been many models using biogas pits to treat livestock waste, which has reduced the problem of environmental pollution."

From the environmental protection efficiency that biogas pits bring, the People's Committee of Thanh Hoa commune (Thanh Chuong) has issued a resolution to replicate the model, and at the same time, allocated funds to support 10 households to build biogas pits to encourage people to use biogas pits to treat waste in livestock farming and protect the rural environment.

One of the criteria that made Ms. Nguyen Thi Kim Tien (Hoa Hieu ward, Thai Hoa town) into the list of "100 outstanding Vietnamese farmers" in 2023, which was just honored by the Central Farmers' Association, is the initiative on clean production and safe livestock farming. Accordingly, with a farm scale of 5 hectares, raising 200 sows and over 2,500 pigs, but when entering Ms. Tien's farm, the air feels very fresh. That is because she has reserved 1 hectare of water surface to grow water hyacinth and water fern, both using water hyacinth as a source of food for pigs and as a natural lake to regulate the air; 2 hectares of green-skinned grapefruit, both taking advantage of waste from livestock farming and helping the farm have trees, shade, and lots of oxygen.

Ms. Tien said: My VAC farm always considers environmental protection very important. All the raw, green food of nearly 3,000 pigs is water hyacinth and water fern; tons of waste are collected every day, mixed with water hyacinth roots, fermented into organic fertilizer for grapefruit; a part becomes raw material for making biogas tanks to cook bran for pigs, and to boil hot water to be led into the system to warm the barn in winter. Thanks to saving costs on food, energy, fertilizer..., the farm's profits are always high, from 5-7 billion VND/year. In 2018, the farm was recognized as meeting VietGAP standards.

Recently, we visited the SunSmat+ farm of Hung Cuong agricultural enterprise in Nghia Thuan commune, Thai Hoa town. The most impressive thing was that on the clean concrete road were rows of ancient single-stem trees, grafted with thin-petaled wallflowers and purple Lagerstroemia, the farm brought fresh and pleasant air. Mr. Pham The Chien, representative of Hung Cuong enterprise, said: "For the farm with an area of 10 hectares, we have worked hard to test the soil to determine the level of degradation and discoloration in order to have a suitable renovation plan, such as buying manure to feed the soil, along with coconut fiber and rice husks to create humus for the soil."

It can be said that this farm is a miniature ecosystem model, operating according to the cyclical chain of livestock and crops; on an area of 10 hectares, divided into many different sub-areas: Greenhouse area for growing grapes and melons; organic vegetable growing area; fruit tree growing area; chicken, pig and cow farming area; fish pond area... The farm's production processes are completely closed, waste and by-products of this process are the input of other processes through the application of scientific and technical advances, biotechnology, physical and chemical technology...

To help us visualize, engineer Hong - working at SunSmat+, gave an example: All by-products of the growing area (vegetables, fruit trees) will be food for the livestock area (cows, pigs, chickens, ducks), the waste from the animals will be a source of organic fertilizer for the plants and food for fish and earthworms; fish and earthworms are natural sources of protein for the animals (chickens, ducks) and plants. All products of the farm do not have to be thrown away; or in other words, not a single by-product is wasted...

We arrived at the livestock area with thousands of chickens, ducks and about 50 pigs, where dozens of workers were busy working. One group was feeding the animals with a diet of pre-processed vegetables, tubers and fruits using small milling machines. Another group transported the waste from this barn to another system of barns to process and raise earthworms, providing dozens of tons/month for animal feed; a part of the waste was composted with biological yeast so that once a month, hundreds of cubic meters of compost could be collected to fertilize all the crops on the farm;

Engineer Hong led us to the greenhouse areas growing tomatoes, melons, baby cucumbers, and green grapes that have been harvested a few hundred meters away from the livestock area. Here, each greenhouse has an area of 1,000 m2, synchronously installed with smart devices for drip irrigation and sprinkler irrigation connected to each bed of plants, below which is a layer of loose soil mixed with organic microbial fertilizers for circular production.

Outside are rows of leafy vegetables: mustard greens, amaranth, Malabar spinach... in the harvest season. After preliminary processing and packaging, all the roots, stems, branches, and leaves are removed and transferred to the compost area; the straw and coconut fiber are then covered with a layer of soil to quickly decompose, creating more humus in the soil for beneficial microorganisms to thrive. Workers set biological traps to attract and destroy harmful insects, protecting the organic ecological environment to develop ideally for beneficial species such as bees, bugs, and predatory spiders...

Dozens of SunSmat+ organic agricultural products are rotated and intercropped on an area of 10 hectares, daily harvesting, processing, and packaging about 2-3 tons of vegetables; hundreds of tons of livestock and poultry meat supplied according to orders from mini-supermarket systems and distribution stores in Nghe An market...

At TH Group's farm in Nghia Dan district - a typical example of green economic development in Vietnam - in all stages, from cultivation to livestock, high technology is applied such as the Afifarm herd management process - Israel; disease and veterinary management process from New Zealand; closed automatic milking system; wastewater and waste treatment process and equipment from Japan, Israel and the Netherlands, using AI technology to count and monitor the cow herd.

In the fields and forests, sensors are used to measure the temperature of the environment and air to report back to the command system to coordinate irrigation and crop care. Cow waste is put into the system to press and separate the manure. After being separated and mixed at a temperature of 65-70 degrees Celsius to kill harmful bacteria, the manure will be mixed with bagasse and some yeast for 45 days to produce organic fertilizer. Organic fertilizer is mainly used to fertilize grass for cow feed, a part is supplied to the market...

After the success of fresh milk, TH Group has produced completely natural nut milk, implemented many projects with rice, peanuts, gac fruit, and organic medicinal herbs in Nghe An and many other provinces to produce world-leading food products...