Leading the movement of applying new technology and using energy efficiently, TH Group Joint Stock Company has invested in production lines and installed smart electrical systems. Along with installing rooftop solar panels on factories and farms in Nghe An, the company also invested in installing a complete system of sensors, automatic lighting bulbs that "turn off when not in use" or automatically adjust the lighting system, cooling according to hourly heat energy, thereby reducing power consumption...

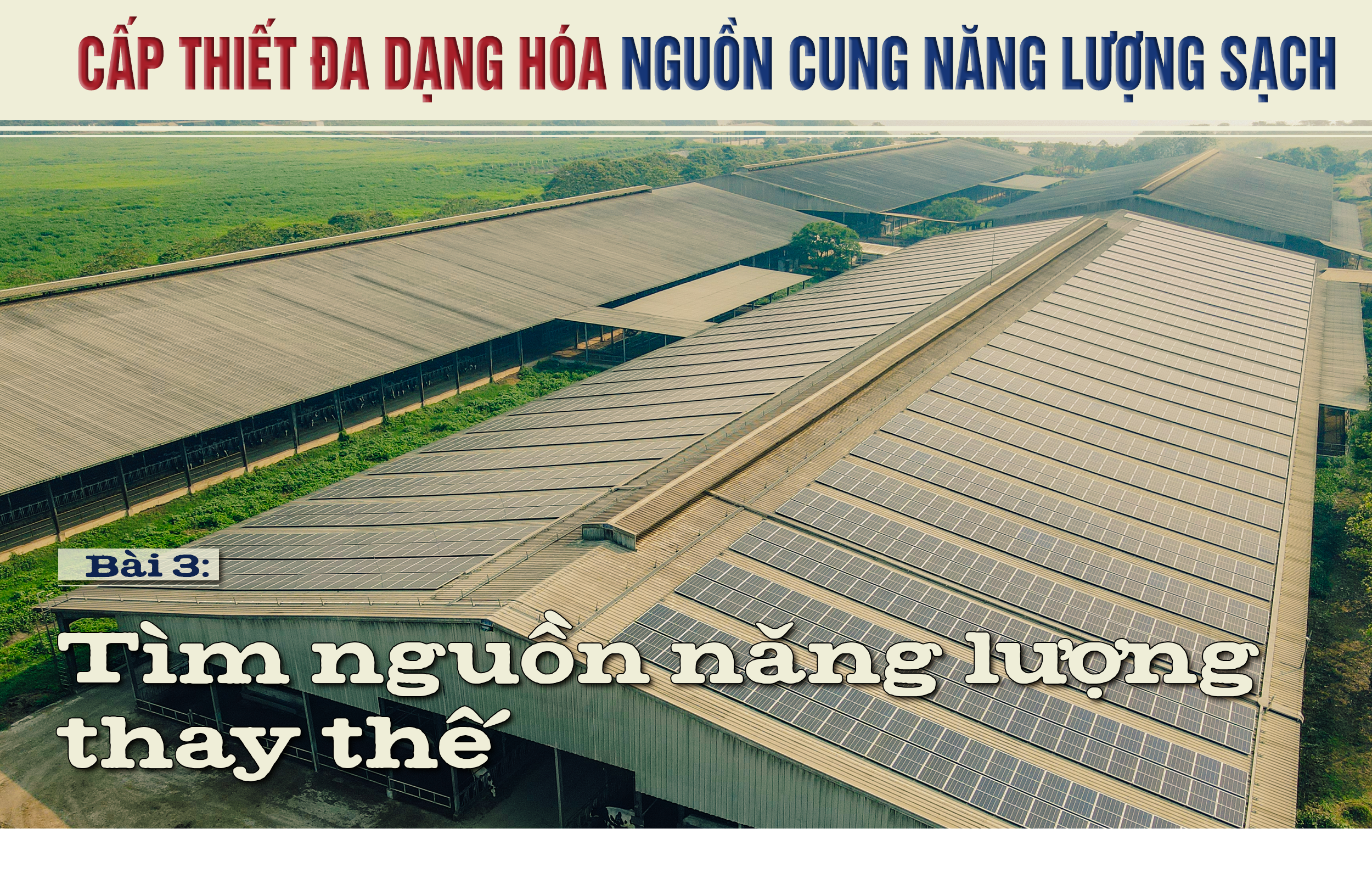

Since June 2020, TH Group Joint Stock Company has deployed rooftop solar power projects at factories. By September 2020, the project has completed the installation and connected to the national grid. With 6 farms using solar energy, the amount of electricity equivalent to 1/8 of the demand (in the summer, the supply capacity will account for 1/5 of the demand), the rooftop solar power system after being put into operation helps the Group save 29,000 kWh/month, contributing to significantly reducing the amount of emissions into the environment. In 2022 alone, approximately 7 million kWh has been connected to the grid (meeting nearly 10% of the electricity consumed at the farm unit), equivalent to reducing/recovering more than 4,500 tons of CO2/year.

Currently, on the roof of the TH Fresh Milk Processing Factory or the Dairy Farm Cluster (Nghia Dan), TH Group has installed a solar power system that not only generates green electricity, but also helps save production costs, contributes to environmental protection, and ensures national energy security. Mr. Pham Vinh Son - Director of Maintenance Department, TH Dairy Food Joint Stock Company said: The company has 9 farms, with a herd of nearly 70,000 cows. The barn system is modernly designed, each cow has its own cage, with an effective ventilation and cooling system on the barn roof; along with that, the processes and equipment to support cow care, milking, barn floor treatment, clean water treatment, wastewater treatment, feed processing for dairy cows, etc. all use electricity.

To improve the efficiency of electricity use and participate in the process of saving energy, reducing CO emissions.2, TH Group is also researching and developing additional biomass power projects at the Nasu Nghe An Sugarcane Production Factory with a capacity of 30MW in the 2023-2026 period, installing additional rooftop solar power systems at the Nghe An Wood Production Factory and other food production factories of the group.

As of mid-2023, in Nghe An alone, TH Group has 9 rooftop solar power projects, covering all roofs including TH Milk Factory, May Forestry Company's Wood Factory; Nui Tien Pure Water, Herbs and Fruit Factory, 5 out of 9 dairy farms, with a total installed capacity of over 9MW.

Mr. Ngo Van Tu - General Director of Nghe An Sugarcane Company Limited shared: We have innovated and improved the technology of existing sugarcane processing factories to diversify non-sugar and post-sugar products such as seasoning powder, alcohol, bio-fuel, paper... to create a closed cycle, bringing efficiency in production. By-products such as bagasse are used to burn boilers producing an average of 9-10MW, the factory uses 6MW, the rest is sold to the national grid - a very useful solution that many businesses have not been able to do.

At Anh Son Sugarcane Joint Stock Company, Anh Son district, for several years now, technology has been applied, whereby the unit takes advantage of waste such as bagasse and agricultural by-products to return to the furnace to serve production. A representative of Anh Son Sugarcane Joint Stock Company said: In the short term, the company is using waste from sugarcane to burn the furnace to produce sugarcane, but in the long term, the company will invest in a technological line to purchase local forest by-products to serve processing at the tea factory and in the long term to produce electricity. If this goal is successfully achieved, the company will reduce production and business costs and implement a closed and circular production process, both taking advantage of agricultural waste and reducing CO emissions.2into the environment.

At Trung Do Joint Stock Company, to save costs and increase competitiveness, taking advantage of the factory infrastructure at the Granite Factory in Bac Vinh Industrial Park, the company invested 15 billion VND to install rooftop solar panels and a transformer system with a capacity of 1MWp. After operating, the company saved hundreds of millions of VND in electricity bills each month. From the success of the rooftop solar production model at the Factory in Bac Vinh Industrial Park, when implementing the project of the High-end Construction Materials Production Complex in Nghi Van (Nghi Loc), along with choosing a new and modern technology line, the company determined from the beginning to take advantage of the factory infrastructure to install rooftop solar panels while taking advantage of tens of thousands of m2factory, thereby reducing heat and producing clean electricity, saving production costs. Mr. Tran Van Hoan - Deputy Director of the company said: Although the capacity is not large, the efficiency is clear. Since the solar panel project, the monthly electricity bill has been from 3 to 3.3 billion VND, but now the electricity bill has decreased to 2.8 billion VND.

To save production costs, many factories, especially cement factories, are applying many solutions to use electricity economically and effectively to help reduce production costs, reduce product prices, and increase competitiveness in the market. The system of collecting heat from the furnace to generate excess heat is a new and advanced European technology solution applied by many countries in the industrial sector. This technology was applied and installed by The Vissai Cement Group in sync with the construction process of Do Luong Cement Factory and has been operating stably since the beginning of 2017.

The system of collecting heat from the furnace to generate excess gas heat operates based on the principle of collecting heat from exhaust gas and excess gas of the clinker production line to get steam to run the turbine generator and generate electricity to the factory's power grid system to serve the production process, contributing to reducing product costs and protecting the environment. Exhaust gas and excess gas after passing through the excess gas power generation system will be clean of dust and cooled before being discharged into the environment. This is the best and most modern environmental protection solution in current cement production technology. According to statistics, each year this system produces over 100 million kWh, providing up to 39% of the total electricity consumption of Do Luong Cement Factory.

According to Deputy Production Director Pham Xuan Khanh: Implementing the plan for energy use and efficiency, Song Lam Cement Joint Stock Company has implemented measures to bring economic efficiency to the company and save energy for society. With the measures implemented in 2022 and until the end of April 2023, the annual electricity consumption has been reduced by more than 12,000,000 kWh, helping to save ~ 7.5% of the factory's electricity consumption in the year, equivalent to 18 billion VND/year; together with the measure of stopping equipment during peak hours, the factory will save 15.5 billion VND/year.

At Hoang Mai Cement Factory, Mr. Nguyen Trung Thanh - Director of Hoang Mai Cement Consumption Enterprise said: To use energy efficiently, since 2021 the company has renovated the kiln, thereby reducing fuel consumption from 810 Kcal to 790 Kcal; at the same time, like other cement factories, the company has invested in a system to filter and collect ash from long-discarded coal slag to make cement additives, thereby reducing environmental pollution. In the near future, the company will invest in new technology to take advantage of excess heat from the kiln to generate electricity; at the same time, invest in a circular waste treatment system, whereby the kiln fuel is not only coal but also other fuels such as tree bark, rags, etc.

For Hoang Thi Loan Textile and Garment Corporation (Vinh City), each month it consumes 3.6-3.7 million kWh of electricity, equivalent to about 4 billion VND in electricity costs, accounting for 40% of production costs, putting the company under many challenging pressures. Therefore, efficient use and saving of energy is also a "vital solution". Mr. Tran Quoc Tuan - Deputy General Director said: From the end of 2022, when export orders decreased, based on the recommendations of the electricity industry, the Corporation rearranged shifts, changed working hours from peak hours to off-peak hours; gradually invested in innovation of energy-efficient technology such as installing new technology lines, installing frequency converter strips. Thanks to that, from the end of 2022 to now, it has reduced nearly half of output and monthly electricity costs, thereby maintaining production and jobs for workers.

Due to the difficulties in production and business, other major customers such as Hoang Mai Cement Factory, Nghi Thiet Cement Grinding Station, Sabeco Song Lam Packaging Joint Stock Company, etc. are also interested in using energy economically and efficiently, and consider it a solution to overcome the crisis. Thanks to the economical and efficient use of energy, businesses can still maintain production, reduce costs to compete, and ensure jobs and income for workers. This activity also contributes significantly to the goal of protecting the environment and national energy security, effectively combating climate change, etc.

Nghe An Electricity representative said: From April 2023, on the basis of Directive 20/CT-TTg and Directive 11/CT-UBND dated June 5, 2023 on promoting electricity saving in the dry season and 2023, Nghe An Electricity will work with enterprises with large electricity consumption to urge and implement the voluntary non-commercial electricity load adjustment program to ensure reasonableness, without major impact on the production and business of enterprises; thereby reducing a part of electricity consumption.

To save costs, many units are applying many solutions to use electricity economically and effectively to help reduce production costs, reduce product prices, and increase competitiveness in the market. Data from Nghe An Electricity shows that, since the beginning of the year, the amount of energy saved in industrial construction production has reached 11.043 million kWh/total amount of energy saved in the whole province is 41.59 million kWh.