Solutions to improve manual brick kilns in Tan Ky

(Baonghean) - Currently, Tan Ky district has 57 manual brick kilns with more than 1,000 workers. In order to eliminate manual brick kilns according to the Provincial People's Committee's Directive, some kiln owners have come up with new solutions to maintain production and protect the environment.

Tan Ky has a large reserve of clay, located along the Con River. Over the years, local people have exploited this potential to produce bricks and tiles. Up to now, there are 170 handmade brick and tile production facilities using clay, with a total capacity of 90 million bricks/year, of which 57 are brick kilns, with an output of nearly 40 million bricks, and a total annual production value of hundreds of billions of VND. There are over 100 households producing bricks and tiles, creating jobs for more than 1,000 workers. For a long time, brick and tile production has been considered a key occupation in Tan Ky, helping many communes to reduce poverty, create jobs and tax revenue in the area.

Ky Son (Tan Ky) is a commune located along the Con River, currently has 12 manual brick kilns. The two manual brick kilns of Mr. Nguyen Xuan Hoai - Hamlet 2 are still operating, emitting smoke into the environment and do not have chimneys. The owner of the brick kiln said: The family built the brick kiln in 2007, worth 300 million VND, with a scale of nearly 1 million bricks/year. The brick market is quite open, supplying bricks to Tan Ky and Do Luong. Currently, the 2 brick kilns create jobs for 8 workers. The family also knows the policy of eliminating brick kilns of the province and district, but wishes to produce all the exploited land to pay off the investment debt. Because the family's brick kiln does not have a chimney, the family will renovate it to operate until December 31, 2014 according to the district's plan.

The owner of Phan Van Le brick and tile kiln (Hamlet 2) said: “My family has 4 kilns producing both bricks and tiles, including 2 tile kilns that invested in emission treatment technology, each costing 1.3 billion VND, and 2 manual brick kilns. All 4 brick kilns currently provide jobs for 21 workers. It is very difficult for my family to eliminate the manual brick kilns at this time because we still owe the bank more than 500 million VND. My family went to Hai Duong and Bac Giang to learn about advanced brick production technology, which is the emission treatment technology using the absorption method transferred by the Center for Mining and Metallurgy Science and Technology under the Vietnam Union of Science and Technology Associations.”

Learning about this technology, we know its process as follows: When burning bricks, exhaust gas is generated in the smoke chamber (the space from the top of the furnace to the roof). The exhaust gas flows by inertia straight up to the roof of the furnace. Therefore, the new technology brick kiln is designed with a closed roof and built with a chimney. The exhaust gas goes straight up to the roof and is led into the smoke chamber. From the smoke chamber, a butterfly valve is installed above to block the smoke. Then, a high-capacity exhaust fan is used to suck the exhaust gas through the smoke channel and bring it back down to the solution tank. In the tank, chemicals including lime milk, activated carbon and some other additives will absorb the smoke along with the toxic gases emitted by burning bricks. These gases are continuously bubbled in the tank, causing a chemical reaction and they are completely absorbed. Clean gas is pushed up by the exhaust fan through the chimney, dust and lime residue that precipitate to the bottom of the tank are taken out through the exhaust pipe. Thus, the toxic gas of the brick kiln is thoroughly treated before being released into the environment.

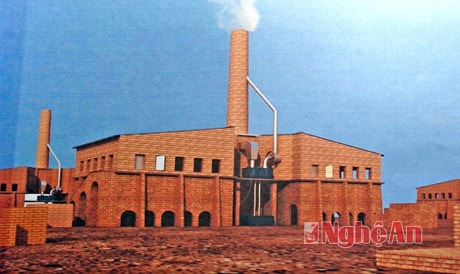

|

| New technology brick kiln model. |

The advantage of this technology is that it is calculated for a brick kiln with a capacity of 250,000 bricks, small scale, low investment capital (the cost of building the kiln shell is about 650 million VND and 400 million VND for exhaust gas treatment equipment), suitable for some people who want to convert from manual kilns. Mr. Vuong Nguyen, the owner of a brick kiln in Hamlet 2, said: “My family also went to Bac Giang to learn and found that the “new technology” brick production technology is very effective. I am determined to convert to a new kiln this year. But to convert, I have to reinvest in the kiln and purchase equipment. I hope to get preferential loans and receive some support from the District People's Committee.”

Implementing the Prime Minister's and the Provincial People's Committee's Directive on inspecting and handling establishments producing handmade clay bricks and tiles and increasing the production and use of unburnt construction materials in the province, Official Dispatch No. 912/SXD-VLXD dated June 19, 2013 of the Department of Construction on the roadmap to eliminate handmade brick kilns, the Tan Ky District People's Committee has established a Steering Committee to eliminate handmade brick kilns in Tan Ky according to Decision No. 58/QD-UBND of Tan Ky District, issued Directive No. 16/2013 on eliminating handmade brick kilns and developing unburnt materials in Tan Ky. Accordingly, handmade brick kilns will cease operations before December 31, 2013; improved handmade brick kilns no later than December 31, 2014; brick kilns using vertical kilns will cease operations on December 31, 2015.

Mr. Nguyen Van Ha - Head of the Industry and Trade Department of Tan Ky District People's Committee said: "The district has thoroughly informed the communes and brick kiln owners, encouraging households to be proactive in the policy of the province and the district. Currently, many households have found technological solutions for their new brick kilns, ensuring no environmental pollution. The district encourages and encourages households to convert, both creating jobs for many workers and preserving traditional occupations, exploiting the potential in the area".

Chau Lan