Prospects of the first plastic recycling model in Nghe An

(Baonghean) - The situation of plastic waste being released into the environment has been causing many serious problems due to its long-term persistence and difficulty in decomposing. Promoting plastic recycling using advanced technology is an approach that is being "tested" in Nghe An and has initially proven its effectiveness, bringing dual benefits to the plastics industry and social welfare.

|

| Plastic recycling at Ha Tien Investment and Development Joint Stock Company. Photo: Thu Giang |

Solving the cost problem

Every year, Vietnam's plastic industry needs millions of tons of raw plastic, but domestic production capacity is only about 200,000 tons. Meanwhile, the fluctuating price of crude oil increases the price of raw plastic, causing the cost of plastic products in our country to also increase and making it difficult to compete with other countries.

The above reality poses a challenge, forcing businesses in the plastics industry to find new directions, one of which is to look for cheaper sources of raw materials such as recycled plastic, and invest in technological lines to promote production from waste plastic.

|

In Nghe An, in recent years, all levels and sectors have paid attention to directing and supporting industrial development in general and enterprises in the plastic industry in particular. The latest example is the model of producing plastic pellets and plastic products from waste plastic at Ha Tien Investment and Development Joint Stock Company, located in Dien Yen commune, Dien Chau district with an electronic color separation line worth about 4 billion VND, supported by 400 million VND from the national industrial promotion fund in 2017.

Accordingly, all kinds of waste plastic bottles, instead of ending their "life cycle" by being buried, will now be "reborn", becoming the input material for a modern and environmentally friendly cycle. After being separated and classified, waste plastic is transferred to the shredder by conveyor belt, undergoes the shredding process and is put into the washing system by a synchronous centrifuge to create high-clean raw materials.

Next, the raw materials are cleaned again through a foreign matter separation system before being spun by a centrifuge to ensure a dryness of 80-97%. Finally, the raw materials are transferred to a grinder, a friction dryer, and through a packaging process to produce recycled shredded PET plastic pieces, exported to foreign markets.

With such implementation, the project has brought many obvious benefits to the business, as shared by Mr. Nguyen Trung Thanh - Deputy Director of the company: "The modern system helps the company save on human resources, specifically since applying the modern production line, we have reduced about 50 manual workers for product quality inspection, saving production costs. Not only that, the more modern production line helps increase output from 3 tons/shift to 10 tons/shift, creating a stable source of goods for export, increasing revenue for the business".

Environmental efficiency

Most notably, the use of advanced technology lines to utilize recycled plastics promises to bring sustainable values to the living environment. First of all, turning waste into useful materials helps reduce waste, saving land area that would otherwise be used to bury hard-to-decompose waste.

Not only that, putting waste plastic into a new “life cycle” also reduces waste treatment costs, while reducing the polluting impact of waste on land and water sources in case of being buried or dumped indiscriminately into the environment.

In addition, through collection, community awareness in waste classification at source and waste recycling will also be raised, along with reducing CO2 emissions causing greenhouse effect due to energy savings. In particular, this process also has an impact on reducing the need to exploit natural resources which have been significantly depleted when compensated by products recovered from the waste recycling process.

According to information from the Nghe An Industrial Promotion and Development Consulting Center, along with other criteria on technology and economic efficiency, the above invaluable benefits have convinced the Ministry of Industry and Trade to approve supporting Nghe An enterprises to build a model for producing plastic pellets and plastic products from waste plastic.

|

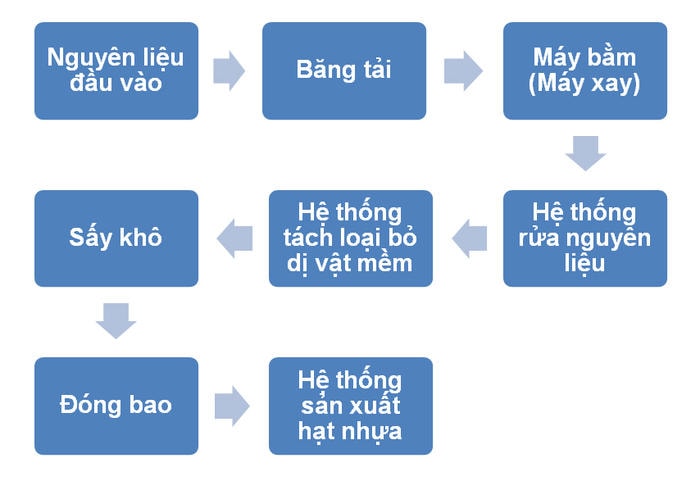

| Diagram: Production process from recycled plastic sources. |

Appreciating the initial positive results, in mid-October, Nghe An Department of Industry and Trade conducted acceptance of the facility and organized a conference to introduce the above technical demonstration model, inviting representatives of a number of provincial departments and branches, along with local leaders and 20 enterprises to "witness", creating conditions for organizations and individuals with investment needs to exchange and learn from experiences.

At that meaningful event, expressing his hope for more positive signals in the coming time, Mr. Bui Tram - Deputy Director of the Department of Industry and Trade emphasized: "This is the first model in Nghe An supported by the Ministry of Industry and Trade and the local Department of Industry and Trade from the national industrial promotion fund this year, with the desire to share part of the funding, encourage and motivate businesses materially and spiritually to be more determined to build the model. We hope that this approach will continue to be replicated in localities, expanding production in the plastics industry in particular and industry in general, towards a future of sustainable development, environmental protection, contributing to the overall development of Nghe An".

Thu Giang

| RELATED NEWS |

|---|