Vietnamese scientist creates device to turn seawater into snow

After two minutes of starting the system, the injected seawater will turn into liquid ice. Depending on the needs, the user can adjust the density of the ice.

Scientists from the Center for High Technology Development, Vietnam Academy of Science and Technology announced that the snow ice making system has been recognized by the Directorate of Fisheries, Ministry of Agriculture and Rural Development as a technical advance in the agricultural sector in the field of fisheries.

This system was successfully implemented by scientists after 18 months of research and design. It can directly use seawater to create ice to preserve seafood caught offshore.

With this new technology, instead of ship owners having to buy freshwater ice from the mainland, then grind it or leave it whole in the cold storage compartment on the ship, they now only need to install the system on the ship, pump seawater through the cooling unit and the output will be snow ice product.

|

Ice making machine installed for testing at Bach Long Vi fishing port. Photo:PP. |

Master Le Van Luan, a member of the research team, said that the advantage of the system of making ice from seawater compared to traditional freshwater ice is that this technology has created a snow-like ice product. In terms of morphology, liquid ice is a mixture of small ice crystals and water, maintained in a temperature range from -6 degrees Celsius to -2 degrees Celsius. This is a transitional state between the liquid and solid phases, so it can be pumped from the liquid ice chamber to storage tanks or fish storage compartments on ships.

The time to produce liquid ice is also very short. Seawater is pumped directly into the system through the circulation tank into the cooling chamber, the output is ice product. That is, just a few seconds after starting the system, the output will be snow ice.

Although the cooling is fast, the melting of liquid ice is much slower than that of freshwater ice. The density of the liquid ice can also be automatically adjusted according to the user's needs.

Because the ice is pumped from the machine to the storage chambers, the ship owner will not have to spend extra labor on crushing and spreading the ice, which will reduce costs and not affect the quality of the fish due to sharp edges of the ice scratching during the storage process.

|

Snow ice machine model installed on the deck. |

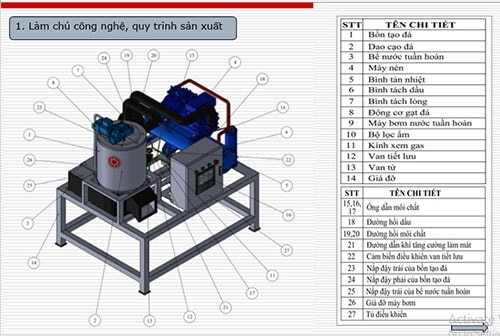

To save installation space, the research team designed the product in the form of separate modules. The ice production part is placed on the deck, the compressor and refrigeration part is placed in the engine room, and the control part is placed in the cabin.

The automatic control software is integrated to adjust the temperature for each different fish compartment, the user only needs to adjust the temperature on the control panel. The machine also has a system that automatically warns when errors occur on the screen so that fishermen know which parts need to be repaired.

The research team also set up software to calculate how many tons of ice the system has produced, how much oil and electricity it has consumed so that users can balance.

The snow ice machine product of the project currently has a capacity of 1,250 kg/24 hours, however the actual demand on fishing boats for each sea trip requires up to 50 - 60 tons of ice to preserve. To achieve this, a machine with a larger capacity is needed, equivalent to about 5,000 kg/24 hours.

To meet practical needs, scientists at the High Technology Development Center are carrying out a State-level scientific task to research and produce snow ice making machines with a capacity of up to 10 tons/24 hours.

MSc. Luan said the product has the same quality as imported products but is only half the price. Because the device is installed on a ship running at sea, scientists also calculated and selected anti-corrosion materials to ensure the durability of the product.

|

Diagram showing the details of the system for making snow ice from seawater. |