Difficulties are still "surrounding" the textile and garment industry in Vietnam in general, including Nghe An. Recently, in the preliminary production summary of the first quarter of 2023, Mr. Vu Duc Giang, Chairman of the Vietnam Textile and Apparel Association said: "Never in the past decades has Vietnam's garment export industry encountered such difficulties and pressure as it does now. Orders decreased from the third quarter, then the fourth quarter of 2022, continued to the first quarter of 2023 and are still decreasing. In the first two months of the year, the export value continued to decrease by 20%. Currently, there are no orders placed for June and July."

Remember, in the last months of 2022, the textile and garment industry had to lay off a large number of workers or cut working hours and income for the reasons mentioned above. The situation is even more difficult for this sector as many countries importing textiles and garments increasingly have higher requirements, which are to improve the quality of goods, reduce prices and comply with environmental standards according to sustainable development standards. This directly affects the Vietnamese textile and garment industry, because most textile and garment enterprises have long been "doing business" thanks to exports. Not to mention many garment corporations in the world are gradually applying advanced artificial intelligence technology to improve productivity, quality and reduce labor costs.

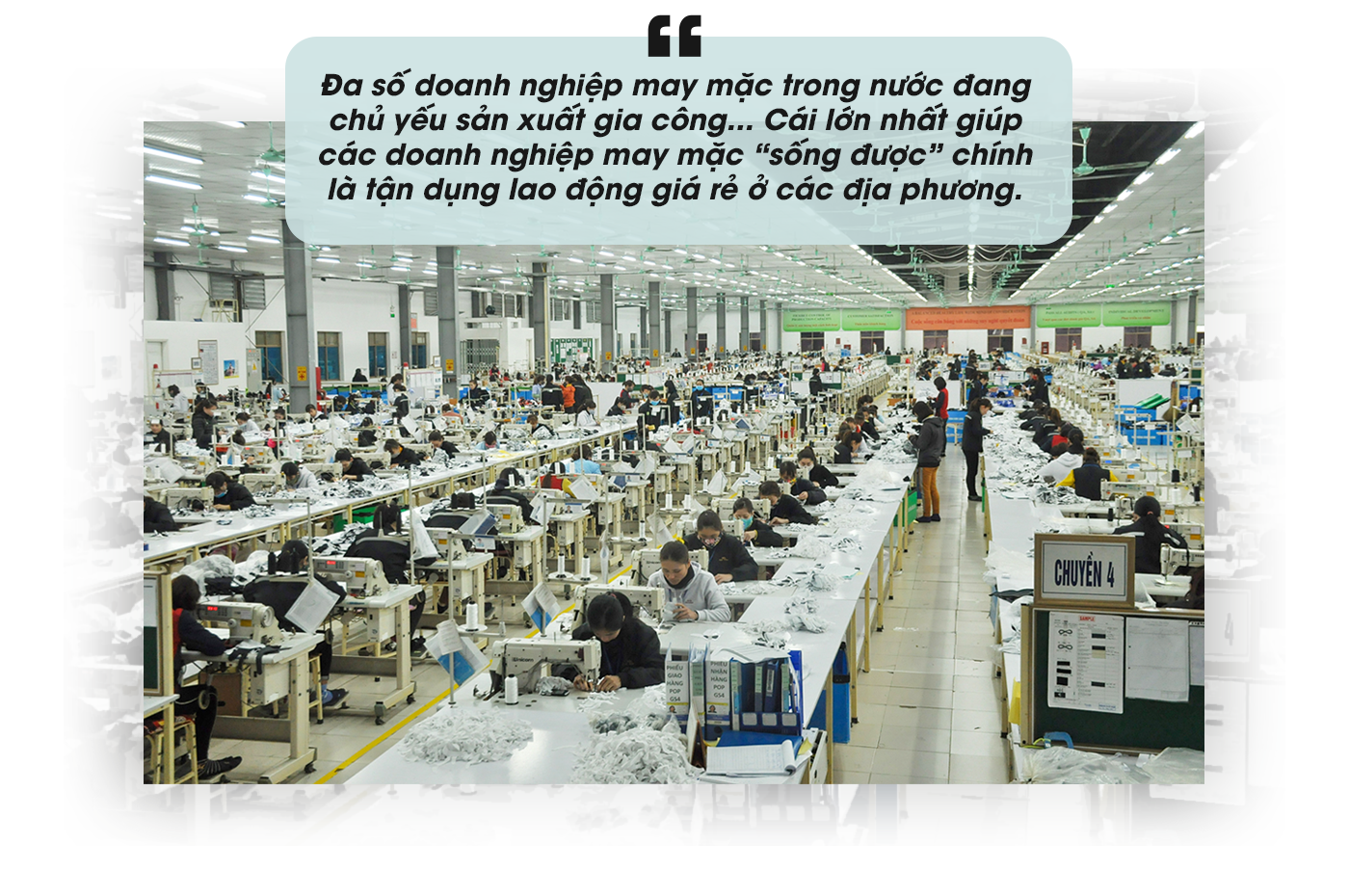

Even more worrying, our country's textile and garment industry has long accounted for the largest proportion of exports, but is too dependent on imported equipment, raw materials and uses a lot of labor (unskilled labor), labor productivity is not high... To be exact, most domestic garment enterprises are mainly engaged in outsourcing production. This activity is based on contracts between foreign enterprises and domestic enterprises. During that process, the ordering party requires the outsourcing party to ensure the design, processing time and some other issues. The biggest thing that helps garment enterprises "survive" is taking advantage of cheap labor in the localities.

Now in many rural areas, we see streams of people going in and out of garment factories, working in shifts. In that large stream of people, the majority are unskilled workers; college and university degrees only account for about 18.24% and there is a shortage of engineers and technical workers. The difficulties of the textile industry are predicted to be facing competition with textile production in countries with abundant labor such as China, Bangladesh, Turkey, India, etc. That reality requires textile and garment enterprises in our country to transform, not just simply manufacturing, but to rise strongly in every stage.

Article: Nguyen Nguyen

Illustration: Thu Huyen