How does the braking process of a container truck take place?

Container trucks are heavy-duty vehicles, so they need special braking systems to ensure safety when moving on the road.

On the afternoon of January 2, on National Highway 1, passing through Binh Nhut intersection, Hamlet 3, Thach Duc commune, Ben Luc district, Long An province, a container truck with license plate 62C-043.48 was traveling at a speed of 45km/h, fluctuating around 54km/h, and crashed straight into motorbikes stopped at a red light, causing many deaths and injuries.

This incident has left many readers feeling confused and afraid of these "highway demons". It is worth mentioning that after crashing into the crowd, the container truck still did not stop even though it was moving at a normal speed on the highway. So, in reality, does the container truck need such a long time to brake?

|

Container truck crashed into motorbikes stopped at a red light in Long An on January 2. |

Time for the driver to stop the container truck completely

The total stopping distance is the distance it takes the driver to perceive the danger, then react by applying the brake pedal, and the distance the vehicle skids on its wheels due to inertia to come to a complete stop.

According to the Utah Department of Transportation website (USA), drivers of fully loaded container trucks (40 tons) will need at least 52 meters to stop completely after braking at a speed of about 64 km/h; if the container is fully loaded and the truck is traveling at about 88 km/h, the driver will need a longer distance, at least 102 meters. All of the above distances do not include external factors such as slippery roads or delayed braking.

However, that is not enough, container truck drivers also need special technical details to help heavy-duty trucks stop more safely, which is the pneumatic brake system.

Pneumatic brake system on container trucks

To stop heavy-duty vehicles (container trucks, buses, trains) effectively and safely, manufacturers do not use hydraulic braking systems but instead equip them with pneumatic brakes. The above vehicles can cause disasters for other vehicles if their speed is not well controlled; meanwhile, using hydraulic brakes is unsafe because there may be brake fluid leaks, one of the causes of brake failure.

|

| Pneumatic brakes are equipped on container trucks. |

The first pneumatic brakes were used for trains of extremely heavy weight. According toEuropean Breaking Systems, previously, trains used an air brake system, but it was a rather crude design, consisting of a compressor located at the front of the locomotive, and a brake pipe running the length of the train and connected to each air cylinder on each car. When the brakes were applied, the system would pump air from the compressor to each cylinder to stop the entire train. Although this braking system worked more effectively than previous types of brakes, it still took too long to pump air to all the cylinders and was very dangerous if any of the air cylinders failed or the brake pipe leaked.

Because of this inconvenience, in 1869, George Westinghouse (founder of the Westinghouse Air Brake Company - WABCO) designed a new pneumatic braking system for trains. Its most important part was a three-way valve, along with an air tank on the train car. This system reversed the braking process of the previous air brake, charging air into the brake pipes to release the brakes, and releasing air from the pipes when the brakes were applied.

|

George Westinghouse - designer of pneumatic braking system for trains. |

Basically, the three-way valve on the train's pneumatic brake system also operates in 3 modes:

- Air charging: When the train is not in operation, the brake pads are always pressed tightly, preventing the wheels from moving. Therefore, the system needs to be charged with air to release the brakes.

- Using the brake: When the brake is applied, the pressure will decrease. When the air volume decreases, the three-way valve will allow the air to return to the tanks; meanwhile, the system also performs the braking function.

- Brake release: When braking, a certain amount of air escapes; then, the pressure in the system increases again to help release the brake.

Then, in 1872, Mr. Westinghouse patented his pneumatic brake system and continued to improve it so that it could be used on other heavy-duty vehicles on the road such as large trucks, container trucks, and buses.

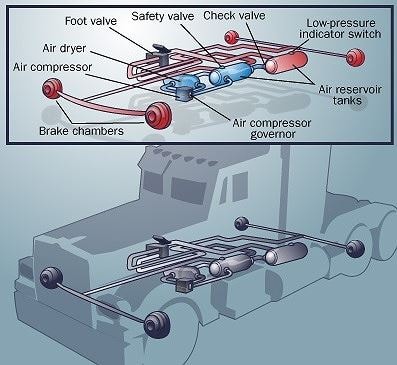

The current pneumatic brake system includes main parts: air compressor, pressure regulator, air tanks, exhaust valve, foot valve (brake pedal), brake chamber, push rod, brake pad clearance adjusting lever, S-type cam, drum brake pads, return spring.

In addition, to achieve the highest level of safety, the air brake also has an emergency brake (parking brake) feature, which can be activated by a button on the dashboard. Before driving, the driver must press this button to pump air into the brake system. Whenever the system reaches sufficient pressure, the emergency brake will not operate. If the system leaks air, the pressure can drop, and when it gets too low, the emergency brake will be activated. This helps container trucks stay safe and not encounter a situation where they cannot brake or lose their brakes.

|

| Structure of pneumatic brake system on container truck. |

However, container truck drivers are still the ones who play a decisive role in safety, no matter how advanced vehicle technology is. Therefore, they are always the ones who need to be alert and focused when driving on the road, because they not only hold their own fate in their hands, but can also affect many other people.