Nissan ASSB 2028: Solid-state battery doubles range, fast charging.

Nissan confirms ASSB cell meets targets, aiming for production in fiscal year 2028; doubling energy density, charging in one-third of the time, and targeting $75/kWh.

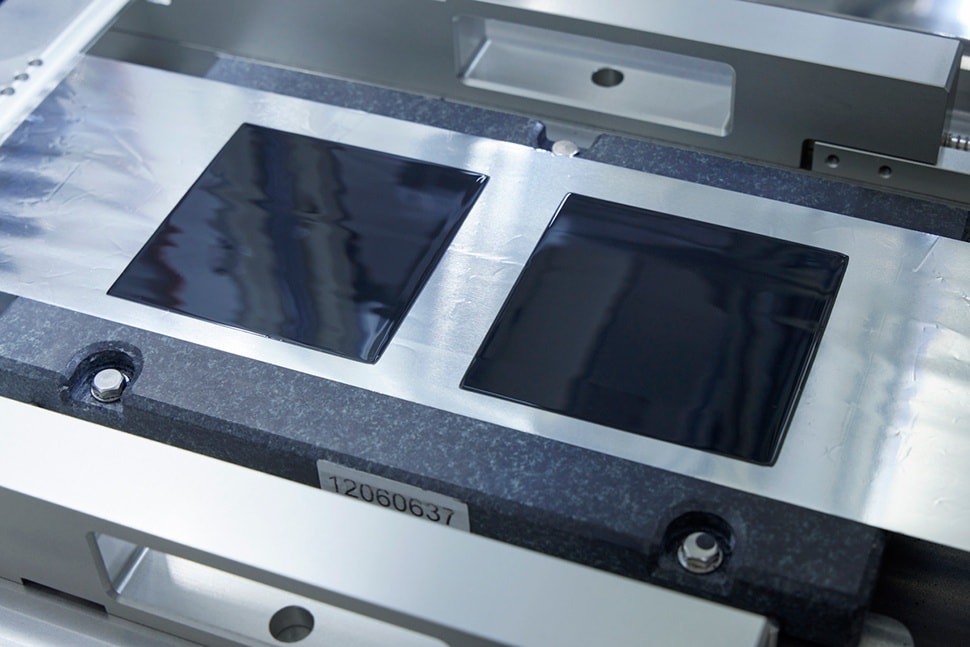

Nissan says its prototype all-solid-state battery (ASSB) has met the performance targets necessary for commercialization, including double the energy density per unit volume and the ability to accept higher charging power, reducing charging times to one-third of those of current lithium-ion batteries. The company aims for mass production in fiscal year 2028.

Nissan's ASSB: A step forward in performance and significance for EVs.

Compared to traditional lithium-ion batteries, Nissan's ASSB has twice the energy density per unit volume. This allows electric vehicles to travel further without increasing the battery pack size. Thanks to its ability to handle higher charging power, charging time is reduced to just one-third, promising an improved driving experience and reduced waiting times at charging stations.

Nissan launched the ASSB prototype in 2022 and maintained a roadmap for commercialization in fiscal year 2028. The fact that the cells have achieved their performance targets is a significant milestone in moving to large-scale production.

Why are solid-state batteries advantageous?

ASSB uses a solid electrolyte instead of a liquid solution, thereby eliminating many undesirable side reactions and maintaining stability at high temperatures. This architecture expands the material selection range for the cathode/anode, making it easier for engineers to optimize overall performance, including energy density, safety, and durability.

Dry electrodes and the role of LiCAP Technologies

To achieve performance breakthroughs, Nissan partnered with LiCAP Technologies (USA) on electrode technology. The key is the “dry electrode” process, which eliminates the drying step in production – a process that consumes energy and costs. This approach helps reduce costs and emissions, but requires precise process control.

LiCAP provides a fibrous binder for the anode (cathode), allowing ions to move more efficiently without clogging the surface of the active material. This enables the creation of high-quality electrodes – a key factor in achieving superior performance in solid-state batteries.

From cell to complete battery: the roadmap to mass production.

LiCAP lacks experience in operating large-scale production lines, while Nissan says it has been running a trial line since January of this year to perfect mass production technology. The next goal is to move from producing individual cells to manufacturing entire batteries, ensuring repeatability in quality and performance to meet the demands of the automotive industry.

In addition to shortening charging times and increasing range, Nissan aims to reduce costs to $75/kWh – approximately 30% lower than the global average in 2024. If achieved, ASSB could help make long-range EVs with short charging times more competitively priced.

Supply chain dynamics and technological competition

Japanese automakers are increasing investment to reduce their reliance on battery supplies from China – a country that holds approximately 70% of the global market share. According to their announced roadmap: Toyota is partnering with Idemitsu Kosan and expects to begin mass production of solid-state batteries as early as fiscal year 2027; Honda is investing 43 billion Yen (US$281 million) to build one of the largest ASSB (Asset-Based Solid State Battery) production lines, aiming for commercialization by the end of the decade.

Outside of Japan, the race is fierce: in the US, QuantumScape (linked with Volkswagen) is expected to begin mass production in 2026 with an annual capacity of 5 GWh; in China, SAIC Motor plans to produce solid-state batteries as early as next year.

Potential impact on EV products

ASSB achieves high energy density, allowing manufacturers to reduce size or maintain a similar size to significantly increase driving range. High-power charging capabilities optimize downtime, opening up opportunities for simpler fast-charging system designs on vehicles. With a target cost of $75/kWh, ASSB can also improve the pricing structure of flagship EV models.

However, to realize this on an industrial scale, the technology needs to overcome several production challenges: uniformity of dry electrodes in large sizes, solid electrode-electrolyte interface, and cyclic durability. The test line that Nissan has been operating since January is a necessary preparatory step to solve the scale problem.

Summary of key objectives and timeline

| Category | Information |

|---|---|

| Cell status | Achieve the performance targets necessary for commercialization. |

| Energy density | Double the capacity in the same volume (compared to lithium-ion batteries) |

| Charging time | That's about one-third of what lithium-ion batteries are. |

| Production process | Dry electrodes; technological collaboration with LiCAP Technologies |

| Cost targets | 75 USD/kWh |

| Production schedule | Fiscal year 2028; trial production line to begin operation in January. |

Conclusion: A stepping stone to a new generation of fast-charging, long-range EVs.

With the confirmation that the ASSB cells meet performance targets, Nissan is taking another step towards commercialization by fiscal year 2028. The combination of solid electrolyte and dry electrode process – along with material contributions from LiCAP – helps the company simultaneously achieve three key goals: long range, fast charging, and competitive cost. In the context of increasingly fierce global competition, the ability to transition from test cells to complete, mass-produced batteries will be key to determining the speed at which ASSB-equipped electric vehicles enter the market.