Smart plastic bottle changes color when water expires

A company called Braskem in Brazil has successfully developed a plastic bottle that helps identify whether the water inside has expired or not through the color change on the bottle cap.

According to Science Alert, Braskem, a plastic and chemical company in Brazil, has successfully created a type of plastic, beverage containers that can change color based on the reaction to the changing pH levels inside. The change in pH suggests that the products may have been damaged due to being past their expiration date.

Although this technology has existed in various forms for the past few decades, Braskem is a pioneer and has certain advantages in developing this technology.

“Braskem has a lot of scale advantages and is well known in this particular sector for good quality products,” said Andrew Manly, communications director of the Association of Packaging Industries (AIPIA).

The $7 billion plastics and chemicals company Braskem is one of the largest producers of materials for bottle caps, jars, reusable containers, cosmetic packaging, and more in the Americas. Braskem has manufacturing facilities in Brazil, the United States, Mexico, and Germany.

|

| Signs of pH change suggest that the products may have spoiled due to expiration. |

The idea for this special plastic technology came from Brazil, a country that has recently been embroiled in a series of food safety scandals, including one in which employees at a food company bribed government inspectors to allow rotten, salmonella-tainted meat to be sold.

"In many countries, we see contaminated food, food packages that are not properly wrapped, food contamination that is rampant during production, transportation and even in supermarkets," said Patrick Teyssonneyre, director of technology and innovation at Braskem.

Meanwhile, many users continue to be confused about the sell-by date and rely on smell to assess the quality of food that is still usable or not. In fact, it is difficult to determine whether food is safe or not by just the senses.

However, to reach a wider audience, Braskem will need to work with food manufacturers and retailers to ensure smooth distribution.

|

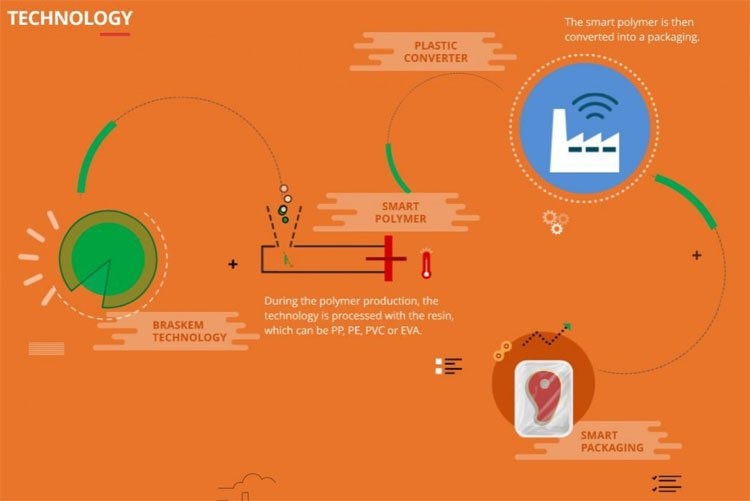

| The production process of a special plastic that can detect the expiration date of the product inside. |

Another concern is cost. According to Meghan Stasz, senior director at the Grocery Manufacturers Association, cost will be a significant challenge for Braskem if it continues to produce these special plastic containers.

Braskem believes that production costs could be reduced somewhat if the technology is widely adopted in the future. Above all, Braskem believes that they can provide a cost-effective solution to the market, especially when compared to the benefits it brings to consumers.

Braskem could even convince food manufacturers to choose Braskem plastics, which offer a number of benefits beyond just being able to tell if a product is past its expiration date. For example, with this technology, consumers can avoid defective products that contain toxic ingredients that are harmful to their health.

|

| With this technology, consumers can avoid defective products. |

The company began researching the plastic technology in 2013 and first released a prototype in 2015. Braskem still needs extensive testing to ensure the plastic production technology can meet all safety standards.

In addition, Braskem needs to understand how readings outside the regulated pH range will affect manufacturers and retailers, and help consumers understand safe limits.

The company hopes to find a potential partner and roll out the smart plastic product to stores in the next two or three years.

According to Khoahoc.tv