How is 3D printing technology creating the future?

(Baonghean.vn) - 3D printing technology plays an important role in revolutionizing the food, fashion, motorsport, healthcare and aerospace industries.

In today’s rapidly evolving technological age, 3D printing stands out as a driving force, redefining creation, innovation, and distribution across industries. From conceptualization to tangible manifestation, its impact is being felt deeply in both academia and industry.

With applications spanning across diverse fields such as healthcare, automotive, construction, aerospace and more, 3D printing is not only breaking down the barriers of traditional manufacturing. It is revolutionizing the way we solve problems, design systems and visualize our world.

This article delves into the multifaceted potential of 3D printing technology. Explore its contributions to various fields and how this cutting-edge technology is set to redefine the future of industries on a global scale.

What is 3D printing technology?

Simply put, 3D printing technology is the process of automatically creating physical models (real samples) from digital models (3D design files on computers) through 3D printers.

3D printing technology is also known as “additive manufacturing technology”, this is a process of producing materials (plastic, metal or anything else) in a layer-by-layer manner to create a 3D object.

3D printing has become an important technology trend in the world and is one of the key technologies of the Fourth Industrial Revolution. According to experts, this is also the "key" technology for the future that any business, any manufacturing industry and any country must pay attention to.

In which areas is 3D printing technology developing strongly?

Nowadays, the applications of 3D printing technology are increasingly widespread, penetrating deeply from macro-industrial fields such as aerospace to basic industries such as food, medicine, fashion, motorsports, education, construction, architecture and art.

Here are the top 5 areas where 3D printing technology is being most widely applied:

1. Food industry

Explore the fascinating world of 3D printed food. Originally known for printing pizzas and pastries, the technology has now expanded to include meat alternatives and lab-grown meat. It has the potential to alleviate the environmental stress of livestock farming and address specific nutritional needs.

As noted in the 2023 3D Printing Trends Report, these 3D printers convert digital designs from computer-aided design (CAD) software into actual, edible products. Unlike traditional printers, 3D printing uses a wide variety of soft or pasty foods, from macaroni and cheese to cookie dough and lab-grown meat.

Food printing is like a pastry chef applying intricate frosting to a cake. The printer’s arm moves along a predetermined path, shaping the food into the intended design. As the operator uploads the design, the food, often in a paste form, is heated inside the machine, not to cook it, but to enhance its flexibility for printing.

Interestingly, the flavor of the 3D printed product corresponds to the ingredients loaded into the printer. The printing process, including exposure to heat, does not significantly alter the flavor.

2. Fashion industry

The potential of 3D printing is making waves in the fashion industry. Renowned designers like Dutch designer Iris van Herpen have used 3D printing to dress celebrities at major events around the world. Adidas and others are commercializing running shoes with 3D-printed midsoles, while Paris Fashion Week 2023 saw multiple brands introduce 3D-printed shoes. Designers are exploring 3D-printed textiles, paving the way for design freedom, customization, and improved material conservation.

The fashion industry has always been at the forefront of innovation, delving into the world of 4D printing. This technology adds a dimension of time to 3D printing, allowing objects to dynamically change their shape or properties in response to external environmental stimuli.

Such systems empower designers to create clothing and accessories that adapt to environmental conditions and the wearer’s preferences. Brands like Adidas are developing 4D-printed shoes that adapt to the wearer’s foot shape and movement patterns, enhancing fit, cushioning, insulation, and breathability, giving athletes a competitive edge.

Experts in the field of 3D printing say that 4D printed textiles will redefine the boundaries of design and function in the fashion industry. Imagine a jacket that can adapt to the cold by becoming thicker, or running shoes designed to increase breathability when exposed to sweat.

Significant strides have been made in the development of self-assembling and shape-changing materials, with a wide range of potential applications, in recent years. The innovations we see today are just the beginning. As the technology matures, the range of applications for 3D printing will undoubtedly expand.

3. Sports racing

The use of 3D printing in motorsports such as Formula 1, MotoGP and NASCAR is on the rise, as it enables faster production of racing parts, resulting in lighter weight and better aerodynamics. In fact, US 3D printer manufacturer Stratasys has partnered with NASCAR and McLaren, while Italian 3D printer manufacturer Roboze has supported Italian motorcycle manufacturer Ducati in the 2022 MotoGP season.

The world’s first fully 3D printed car was unveiled by the American car manufacturer Local Motors in 2014. The car took just 44 hours to print and could reach speeds of up to 50 miles per hour. However, 3D printing in the automotive industry goes beyond finished cars, playing a major role in the creation of prototypes and various car parts.

The upcoming 2024 Cadillac Celistiq luxury car produced by the famous car company Cadillac is expected to have more than 100 3D printed components. This car is dubbed by the manufacturer General Motors as “the most technologically advanced Cadillac ever” and is the one with the most 3D printed parts.

Motorsport teams actively collaborate with 3D printing companies as the technology offers a competitive advantage, assisting in the production of lightweight, aerodynamically efficient parts to reduce lap times.

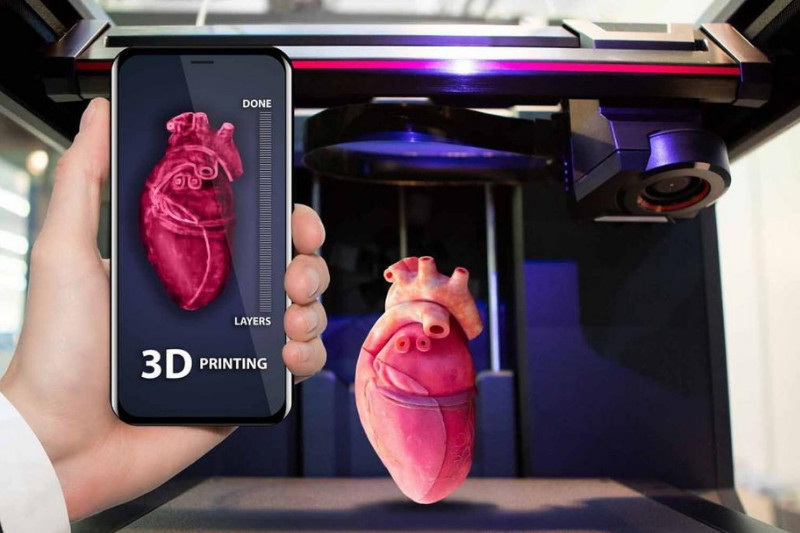

4. Health care

In medicine, 3D printing technology has been applied to produce biological tissues, anatomical models of human body parts (bones, teeth, artificial ears, etc.). This technology is also used to support testing of new medical methods and technologies, enhance medical research, and teach and train medical staff.

The application of 3D printing technology in healthcare facilities will create a paradigm shift, paving the way for personalized medical solutions, increasing efficiency and improving patient outcomes. Another breakthrough solution is 3D printing of biological tissues (Bioprinting), which has the potential to revolutionize healthcare. 3D printing of biological tissues is a method that uses 3D printing and 3D printing-like techniques that combine cells, growth factors and biomaterials to fabricate biomedical parts that closely mimic natural tissue characteristics to significantly advance tissue engineering, especially in drug development testing and regenerative medicine.

Although 3D printing of biological tissues is still largely in the research and development stage, it is expected that it will be possible to produce human body parts for replacement and transplantation of damaged organs.

The dental industry is also using 3D printing to create implants, crowns, retainers, dentures, and anatomical models. The range of applications for 3D printing extends to the creation of hearing aids, surgical models, and pre-operative planning aids.

3D printing has made a name for itself in the healthcare industry, creating custom prosthetics and medical implants. However, existing techniques can be time-consuming and resource-intensive.

Artificial intelligence (AI) technology is now widely applied in various fields such as art, literature and software development. Tech experts expect that AI can also drive advances in 3D printing technology in the coming time. By making additive manufacturing faster, more efficient and hopefully more accessible and user-friendly, AI can democratize the technology to the point where using it becomes as simple as operating an office inkjet printer.

5. Aerospace

3D printing technology has revolutionized the aerospace industry, supporting spare parts manufacturing, satellite manufacturing, exploration of lunar and Mars habitats, and rocket engine manufacturing. Notably, Relativity Space, a space startup, has accelerated the production of rockets using this technology, with the first fully 3D printed rocket, Terran 1, successfully launched into space in March this year. This launch confirmed the viability of 3D printed rockets, heralding a new generation of rockets in aerospace manufacturing.

Following the anticipated success of Terran 1, focus will shift to Terran R, a reusable rocket capable of medium to heavy lift. Experience and data gained from the Terran 1 program will significantly inform the development of Terran R.

In addition to 3D printing, 4D printing technology is also transforming the aerospace industry. Research shows that 4D printed drone wings can adjust to different flight conditions, reducing air resistance and improving performance and fuel efficiency. The technology can also create lightweight, flexible structures for satellites and spacecraft, simplifying space missions and reducing costs.

In addition, the benefits of 4D printing technology will also resonate in other areas of transportation. 4D printing is particularly suitable for the automotive, aerospace and marine industries, where there is a strong interest in manipulating structures for aerodynamic purposes.

The significance of 3D printing technology in daily life

3D printing technology promises to have a significant impact on our daily lives. In the food sector, home 3D printers can create meals tailored to specific dietary needs and preferences. This not only adds visual appeal but also promotes healthier eating habits.

In the fashion industry, 3D printing could enhance personal expression through customized, perfectly fitting clothing. Additionally, 4D printed clothing and shoes that adapt to environmental conditions could bring new levels of comfort and functionality to our wardrobes.

Transportation will also undergo a transformation. 3D printing can create lightweight, durable parts that help create vehicles that are more efficient, safer, and more personalized. This innovation can lead to an improved driving experience.

Advances in healthcare could include personalized medical solutions such as custom-fit prosthetics, dental implants, and potentially bioprinted tissues for transplants. These developments could significantly improve quality of life and extend lifespan.

3D printing technology could make space travel more accessible by allowing spare parts to be printed in space and facilitating the construction of habitats on the moon and Mars.

In short, 3D printing technology will help create dynamic structures that can change according to our needs, leading to more energy-efficient, safer, and more efficient devices.