Nghe An textile and garment enterprises struggle during the epidemic season

(Baonghean.vn) - Garment enterprises are receiving optimistic signals as many orders increase, but the complicated developments of the epidemic have caused this sector to face many challenges. Labor shortages and high input costs are obstacles for the textile and garment industry.

Shortage of workers due to epidemic

|

| Currently, textile and garment enterprises proactively place orders to ensure jobs for workers. Photo: Thu Huyen |

Nghe An currently has more than 20 garment projects that have been invested in, built and put into operation, creating jobs for more than 25,000 workers, mainly in rural areas. In addition, more than 10 other projects in the province have been and are undergoing new investments or capacity expansion.

Mr. Nguyen Van Hiep - Head of Industrial Management Department, Department of Industry and Trade said: Although the Covid-19 epidemic is complicated, the supply chain of textile materials is not broken. The current encouraging signal for textile enterprises is that orders are abundant, production continues to grow with export turnover in the first 6 months reaching 139 million USD, up 34.5% over the same period. In early 2021, many textile enterprises in Nghe An have signed orders until the end of the year and the following year.

|

| Textile and garment enterprises strictly implement epidemic prevention and control measures to maintain stable production. Photo: Thu Huyen |

To performdual goals of economic development and epidemic prevention and controlEnterprises proactively equip themselves with alcohol sanitizer, masks, rapid testing, and develop work plans, arrange safe accommodation, pick up and drop off workers, etc.

However, businesses are also struggling with many difficulties:labor shortage, lack of export containers, increased production costs... affecting profits, many orders at risk of not meeting progress are concerns of businesses.

According to the reporter's investigation, currently Hoang Thi Loan Textile Joint Stock Company only has 1/3 of its workers operating machines; Minh Anh - Kim Lien Garment Company is short of 500 workers; Prex Vinh Company Limited is better off but its capacity is less than 90%...

“Many workers have to be quarantined, causing the production line's capacity to not reach capacity; because some localities are locked down, social distancing is practiced to prevent and control the epidemic, and transport vehicles are strictly controlled, so the cost of transporting goods in and out has also increased, taking a lot of time and effort of businesses,” Mr. Tran Duc Long - Chief Accountant of Prex Vinh Company Limited worried.

|

| Minh Anh Garment Company - Nghe An deploys Covid-19 testing for workers and laborers. Photo: Thu Huyen |

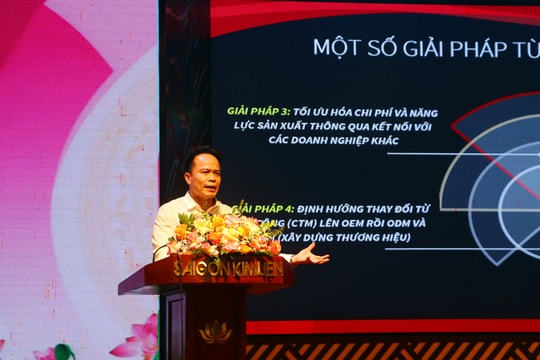

Mr. Nguyen Dinh Vinh - Deputy General Director of Minh Anh Garment Joint Stock Company - Nghe An shared: Our biggest difficulty right now is the shortage of labor and high production costs. At the time when Vinh city implemented Directive 16 and maintained epidemic prevention and control checkpoints, many workers in the districts could not enter Bac Vinh Industrial Park to work. Many workers in communes in Thanh Chuong, Nam Dan districts and Ha Tinh province had to quarantine at home.

Container rental prices hit record high

Not stopping there, most import and export enterprises are stuck because of the lack of containers, the rental price of containers has increased but there are no containers to rent, greatly affecting the import and export plan. Currently, the inventory of Minh Anh - Kim Lien Garment Company is about 100 containers, and they have to rent a yard to store the goods.

|

| Many garment enterprises in Nghe An have arranged accommodation and meals for workers to ensure epidemic prevention and maintain production. Photo: Thu Huyen |

To maintain production, we have to arrange vehicles to pick up and drop off workers. For example, Minh Anh - Kim Lien Garment Factory has more than 3,000 workers, of which 1,500 are concentrated in the districts. Every day, the company has arranged nearly 100 round-trip trips to transport workers, ensuring the principles of epidemic prevention and control. Then, rapid Covid-19 testing for thousands of workers also causes costs to increase. Some orders have been issued but the disbursement is slow because the customers are also affected by the epidemic.

Sharing this difficulty, the leader of Hoang Thi Loan Textile Joint Stock Company said that currently the number of machine operators is only 1/3; some workers live in the company. In addition to the difficulty of not having enough machine operators is the problem of transportation costs. Every month our company needs about 40 containers to go back and forth but currently there are none; Since the end of 2020 until now, the transportation cost has increased cumulatively, and now the sea container shipping cost on some routes continues to increase at a record level.

|

| Containers are loaded and unloaded at Cua Lo Port. Photo: Thu Huyen |

For example, the shipping fee from Hai Phong Port to Europe used to cost about 1,500 USD/container, but now it is at 7,000 - 8,000 USD/container; from Hai Phong to the US before the pandemic was less than 1,000 USD/container, but now it has exceeded 10,000 USD. Besides the high shipping cost and the difficulty in booking a place on the ship, there are also no empty containers to rent, and the companies are constantly delaying. Currently, businesses have to export goods to Egypt but there are no containers, similarly, containers importing raw materials from Singapore are also expensive.

|

| Due to labor shortage, Hoang Thi Loan Textile Factory currently has only 1/3 of its workers operating the machines. Photo: Thu Huyen |

According to the leader of the Department of Industry and Trade, in the current complicated epidemic situation both domestically and globally, although textile and garment orders have returned, in order to develop sustainably and overcome challenges from the epidemic, textile and garment enterprises really need support policies from the State. In addition to reducing and extending taxes, fees, bank interest rates, etc., there should be favorable policies for domestic and foreign investors to build closed textile and garment chains, thereby increasing the capacity of domestic enterprises, increasing export quantity and value, increasing profits, etc.

According to the Ministry of Industry and Trade, regarding the increase in container freight rates, representatives of shipping lines explained that the impact of the epidemic has caused the release of goods and the rotation of empty containers to be prolonged. In addition, the sudden increase in the amount of goods exported to Europe and the US has led to a shortage of empty containers for packing goods.

In response, shipping lines also proposed that authorities consider resolving the situation of thousands of unclaimed containers at ports to "source" empty containers for export.