New solutions for construction projects

(Baonghean) - With new technological solutions applied and improved techniques, many difficulties and complexities in construction have been gradually overcome.

|

| Workers of TSC Steel Joint Stock Company install steel components at the construction site. Photo: Duc Anh |

Surely many people still remember the image of dozens of workers struggling with straightening, tying steel bars, then vigorously mixing concrete by hand, then passing it to each other to pour the roof and cast beams. Besides, to cast concrete for a construction project, people also need dozens of cubic meters of wooden formwork and it takes many days to form the mold. The day the concrete is poured is considered an extremely important day.

In the construction industry, there are 3 categories that have a great impact and determine the quality of the project. They are concrete, steel and formwork (concrete molds).

With the new technological solutions applied, the techniques improved, many difficulties and complexities in construction have been gradually overcome. However, there are still problems that need to be solved. One of them is construction steel.

|

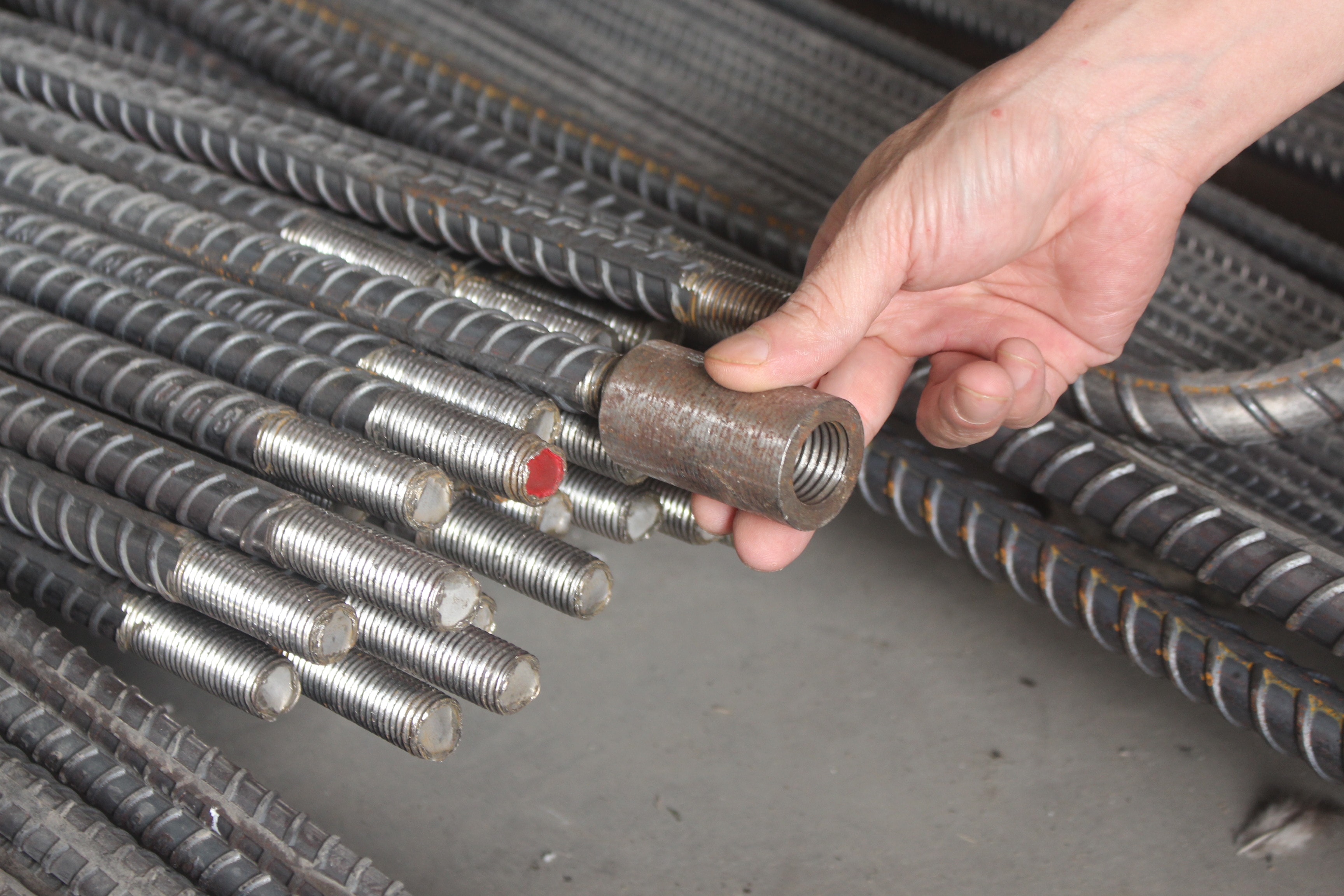

| Couplers connect steel bars to create solidity for the construction and are a solution to save 7-10% of costs. Photo: Dao Tuan |

Concerns about safety during the labor process, construction time, and construction costs make it difficult for investors and project owners to control. In particular, for iron and steel, one of the core materials that determines the durability and longevity of the project, it is often done manually. These are sieves, pillars, beams, steel structures, etc. that are measured on site and tied quite simply.

And it also takes many workers to do this step for many days. This not only slows down the project but also costs a lot of money while the safety and quality are not high. "A floor with an area of about 1,500m2, to carry out the steel construction will need about 50 workers and work for 4-5 days. This reality will make investors, project owners and contractors have to calculate" - Mr. Le Quang Trung - General Director of TSC Steel Joint Stock Company, headquartered at No. 34, Tran Quang Dieu, Vinh city said.

More than 12 years of experience in supplying construction steel for projects in many provinces and cities makes Mr. Le Quang Trung constantly think. Mr. Trung said that instead of old methods, some technological solutions in the construction industry have been applied and brought about efficiency, such as: using aluminum molds instead of wooden formwork, forming fresh concrete mixing plants to meet customer needs. As for steel, it has not changed, most projects are still being done in the "classical" way. To overcome this reality, there needs to be a pioneer.

From the anxieties of a person working in the commercial steel industry, Mr. Le Quang Trung cherished the plan to find a way to overcome the limitations of traditional steel construction.

And a rare opportunity came to him. In 2015, during a meeting and working with a customer, Mr. Trung met Mr. Akisawa - Director of Kyoei Sangyo Company - Japan's largest steel contractor. Through Mr. Akisawa, Kyoei Sangyo Company transferred technology, provided machinery support and technical guidance to TSC Steel Joint Stock Company. In addition to Kyoei Sangyo's technical support for high-rise steel buildings, TSC also learned about the technology of constructing steel bridges and roads from the American Harris Rebar Group.

|

| Steel structure processing at the factory. Photo: Duc Anh |

Since 2017, TSC Steel Joint Stock Company has started to process and produce steel components using new Japanese technology solutions. Instead of supplying 11.7 steel bars, TSC has supplied according to construction drawings. Orders are processed and manufactured at the factory before being shipped to the construction site. The notable point of this solution is the use of steel couplers instead of the traditional tying method.

According to the Coupler steel connection method: 2 steel bars are connected concentrically so they act as a continuous length of steel bar. This does not occur interruption when transmitting force. Besides, the strength of the joint does not depend on the strength of the concrete or the adhesion between the concrete and the steel. The joint has a good load-bearing cycle even when the protective concrete layer is destroyed under the impact of cyclic loads.

Meanwhile, the traditional method is that the steel is connected eccentrically. Accordingly, when it is necessary to extend the length of the steel bar to meet the design of the project, the 2 sections will be fixed and connected together by tying. A formula given for this method is: 30-40cm x D. (In which D is the diameter of the steel). Assuming that with steel diameter 30, the length of the connecting section will be 40x30=120cm. This eccentric method makes the force transmission not be performed directly but indirectly through the concrete. Therefore, the bearing strength of the connecting section depends on the strength of the concrete and the adhesion between the concrete and the steel. In addition, with the traditional method, it will both waste steel and take time in construction.

The application of steel processing model according to Japanese technology has made TSC Steel Joint Stock Company the first unit not only in Vietnam but also in Southeast Asia to apply this technical solution. In fact, the new method of steel processing and production also helps the project save 7-10%. In addition, the construction and installation according to industrial methods, pillars, beams, floors, walls (for high-rise buildings); bored piles, pedestals, bodies, and beams for bridge projects are manufactured in the factory, and only assembled at the construction site, so the progress is 5 times faster than usual. And more importantly, the accuracy, durability, and quality of the project always meet optimal requirements.

According to Mr. Le Quang Trung, each steel processing line with a capacity of 100 tons/day of the Japanese company TOYO must invest 15 billion VND. Up to now, the company's department has localized 30%, and in the near future this number will be 80%.

|

| Technical staff instruct on bending steel according to design. Photo: Dao Tuan. |

In addition to steel contracting and construction, TSC also provides structural consulting for high-rise buildings and bridges using high-grade reinforced concrete, saving investors tens of billions of dong.

TSC is also a pioneer in researching and manufacturing new technological lines. Recently, to construct high-tech steel, the company has used special crane hooks. If this crane hook were purchased from Japan, it would cost tens of thousands of dollars. However, after research, the company has successfully produced it at a cost of only 10 million VND, thereby saving hundreds of millions of VND.

"Using this method, we have successfully constructed and installed many projects at VSIP Nghe An Industrial Park. Bridge projects in San, Chieng, and Quang villages (Quy Chau district - Nghe An) were also constructed using this method" - said Ms. Nguyen Thu Ha, Deputy Director of TSC Steel Joint Stock Company.

In its development strategy, after its success in Vinh City, TSC Steel Joint Stock Company has expanded its production scale, with factories present in many localities across the country, such as Hanoi, Da Nang, and Ho Chi Minh City. And at the end of March 2018, the company will officially open a factory in Phu My Industrial Park, Ba Ria - Vung Tau Province. Initially, this factory will produce 100 tons of steel per day, then with 10 production lines, it will reach a capacity of 1,000 tons per day. "According to the plan, by 2020 we will be present in all provinces and cities across the country with an average capacity of 50 tons of steel per day" - Mr. Le Quang Trung, General Director of TSC Steel Joint Stock Company shared.

Mr. Trung also affirmed that TSC Steel Joint Stock Company's vision will be to be the leading steel contractor in Asia with the mission of saving and automating the construction industry.