Micro needles dissolve in the skin

The fear of needles is now a small matter thanks to a new replacement device invented by researchers at the University of Texas, Dallas (USA).

The new method still injects drugs into the body, but with a tiny needle and without causing any pain. The needle is so thin that it dissolves under the skin once enough drug has been injected. Although not universally applicable, this injection can deliver a wide range of drugs made from compounds with small molecular sizes.

According to the paper published on ChemRxiv, the research team explains: the injections were produced using fused deposition modeling (FDM) 3D printing. This is a rapid prototyping technology that uses a CNC-controlled (automatic mechanical processing) injection nozzle to melt and extrude flexible filament material to create a cross-section of the sample.

The material used to make the needle tip here is polylactic acid – a thermoplastic, biodegradable plastic that is certified by the US Food and Drug Administration.

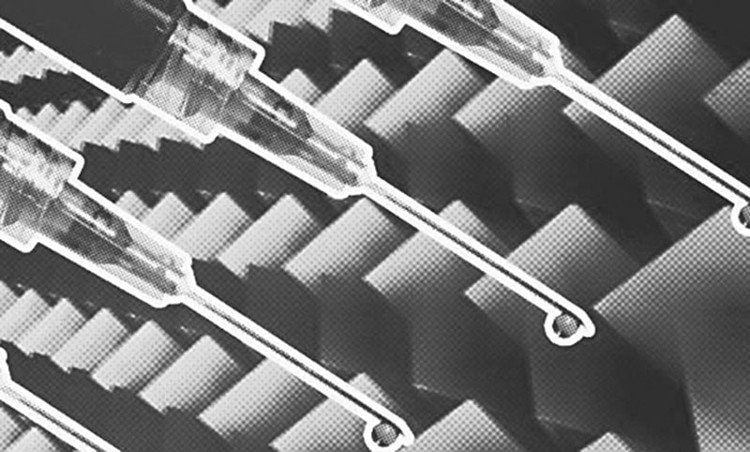

The tiny injection can dissolve just under the skin. (Photo: Futurism).

To achieve the desired shape, the needles are chemically etched after printing. The needle tip size is as small as 1 micrometer (106m) and 400 - 600 micrometers wide. For comparison, a human red blood cell is about 5 micrometers in size.

Currently, subcutaneous injections are still considered the standard for vaccination, but they can be painful and leave unsightly bruises if not performed correctly. At the same time, waste from used injections is also a source of dangerous biological pathogens. Therefore, this type of micro-needle was invented to solve the above problems because it is painless, can be used for many subjects and does not create waste.

However, this type of needle still has a disadvantage: although it can be produced at a low cost, the equipment needed to serve 3D printing is quite expensive. However, tests on parafilm paper and pig skin have brought positive results when 84% of the injections were dissolved.