5th grade farmer invents unique tea-kneading machine

Coming to Tan Cuong (Thai Nguyen), everyone knows the name Pham Trung Tuyen. Although he only finished 5th grade and did not receive any formal training, this old farmer born in 1961 still created a unique tea-crushing machine, earning billions of dong each year.

| Clip of Mr. Pham Trung Tuyen producing tea rolling machine. |

For over 20 years, Mr. Tuyen's rolling machine has become a familiar means of production in every family in Tan Cuong tea region and tea growing localities across the country, even exported to Laos.

Without formal education, all his achievements were created by his own creativity, self-discovery and determination. When asked if he had any experts, scientists or doctors to advise and help him, he said he still did it himself and really hoped to meet them one day to get advice and help... to make his products more and more perfect.

The old farmer's machine has no degree

Born and raised in Tan Cuong (Thai Nguyen), the place known as "The world's number one tea", Mr. Tuyen understands better than anyone else about his hometown's traditional craft.

Returning from the Northern border war in 1979, he started a career with tea trees.

At that time, the facilities were still rudimentary, so production encountered many difficulties. Processing steps such as picking, rolling, roasting, and drying tea were all done manually, leading to low productivity and quality.

|

| A 5th grade farmer researched and made a tea-kneading machine to sell all over the country. |

Only later, when applying technology to production, people learned about supporting tools such as rotating corrugated iron and rolling machines. However, the weakness of these tools is that they are difficult to use and do not meet the requirements of the product.

“At that time, I tried to save money to buy a corrugated iron reel to use. But when I bought it, it couldn’t be used, so I was so angry that I took it apart and remade it according to my own ideas. It’s true that in need comes invention. After many failures, I successfully made the first corrugated iron reel and later the tea-crushing machine,” Mr. Tuyen confided.

Mr. Tuyen made corrugated iron for 2 years and then changed direction, because according to him, making corrugated iron was both hard work and not profitable, while the market was "thirsty" for a real tea-crushing machine.

In 1997, the 5th grade farmer started researching to create a unique kneading machine. He started to collect and analyze the necessary features of a dream machine with the first sketches.

“When I finished the drawing, I asked the teachers at a nearby school if I had drawn it correctly because I had only finished 5th grade and was not good at math. But when I brought the design to them, they were stumped. They said they had never seen such a strange pattern before,” he said.

Not giving up, he kept learning and working on his own, based on his previous experiences in making rolled sheet metal. Occasionally, he went to a nearby Chinese lathe workshop to see how the machines worked and to modify them accordingly.

|

| The tea kneading machine is made of iron instead of wood like in the first period. |

|

| At the age of 57, Mr. Tuyen still does all the machine manufacturing steps himself. |

Perseverance pays off. After many days of hard work, old farmer Pham Trung Tuyen launched his first tea rolling machine at the end of 1997. Immediately, his product created a buzz in the tea market and was loved by many people.

Mr. Tuyen said: “The first tea-crushing machine was made 100% of wood, and later I improved it with iron to make it more suitable. There is a family that is still using the first generation of wooden machines. I plan to go over there in a few days to talk about buying it back to display as a souvenir.”

Not only is he the "king of tea-crushing machines", he is also known as a genius by the villagers because he also invented many other types of machines, especially three-wheeled vehicles, barges used in repairing cars and motorbikes, winches, conveyors, door spokes, etc.

Overcoming difficulties with strong will and passion

“People keep calling me a daredevil or a man of many talents and many faults. Actually, sometimes being daring has its advantages because it will create breakthroughs, but being too daring also has its disadvantages because you will have to suffer the consequences for the rest of your life,” he concluded.

|

| The "king of the washing machine" has no degree of tools. |

In 1998, at the peak of his career, an accident suddenly struck the talented farmer, leaving one of his eyes permanently damaged.

“At that time, I was turning a wooden pulley when suddenly a sharp 30mm piece flew off the shaft and pierced one of my eyes. I suddenly fell to the floor, blood flowing from my eyes and nose. There was no one at home at that time, I thought I was dead,” he said sadly.

The three months of hospitalization were a crisis for him. One of his eyes was so badly injured that it was permanently damaged. For him, the pain was not as terrible as the mental deterioration and his own despair.

After the most painful moments of his life, the "king of washing machines" decided to stand up and stand up strong.

With his passion in his blood, he began to expand production, invest in machinery, and hire more workers to meet market demand. Day by day, Mr. Tuyen has affirmed his name in the tea processing industry.

The unique rolling machine is gradually being sold widely in tea growing areas across the country such as Thai Nguyen, Tuyen Quang, Lam Dong and recently exported to Laos.

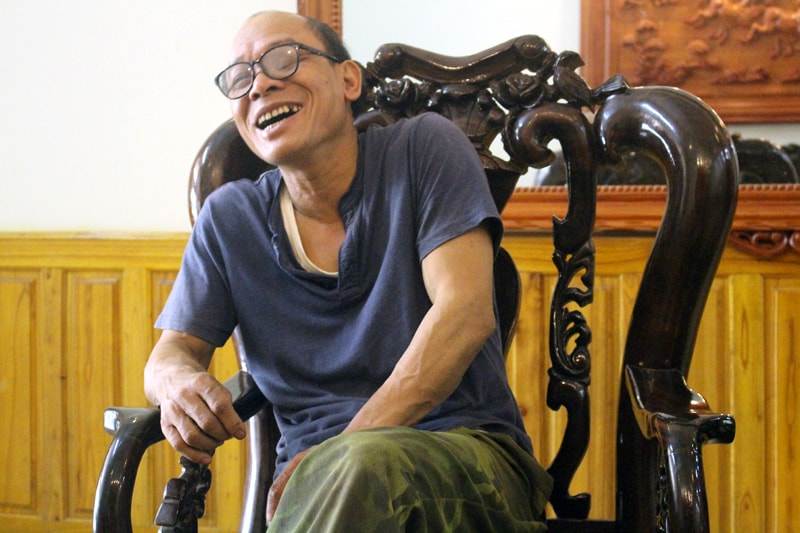

|

| Mr. Tuyen's refreshing smile after hours of hard work. |

In 2017, he produced nearly 300 machines, costing 4.3-4.5 million VND/unit. Excluding raw materials and labor, Mr. Tuyen earned a profit of more than 2 million VND/product, not including the money earned from selling accompanying tools.

“On average, I make one rolling machine a day, but I sell out as soon as I make one, and sometimes I have to pay back orders. During peak season, I often have to wake up at 4am to make machines for customers,” he confided.

Since the beginning of 2018, Mr. Tuyen’s tea-crushing machine purchases have increased dramatically, 2-3 times higher than previous years. From the 5th day of Tet, he immediately started working.

Normally, to buy a machine made by him, customers have to order 1-2 weeks in advance.

When asked why he doesn't hire more people to make the job less difficult, Mr. Tuyen said finding people is easy but keeping them is difficult.

According to him, the hardest part of being a craftsman is passion. You have to love and be passionate about what you create to be successful. Many people have studied with him but all gave up because they couldn’t handle the pressure, including his son.

“I often advise people that if they are truly passionate, they should study because work is something that will last a lifetime. Sometimes a career can depend on the person pursuing it,” he said.