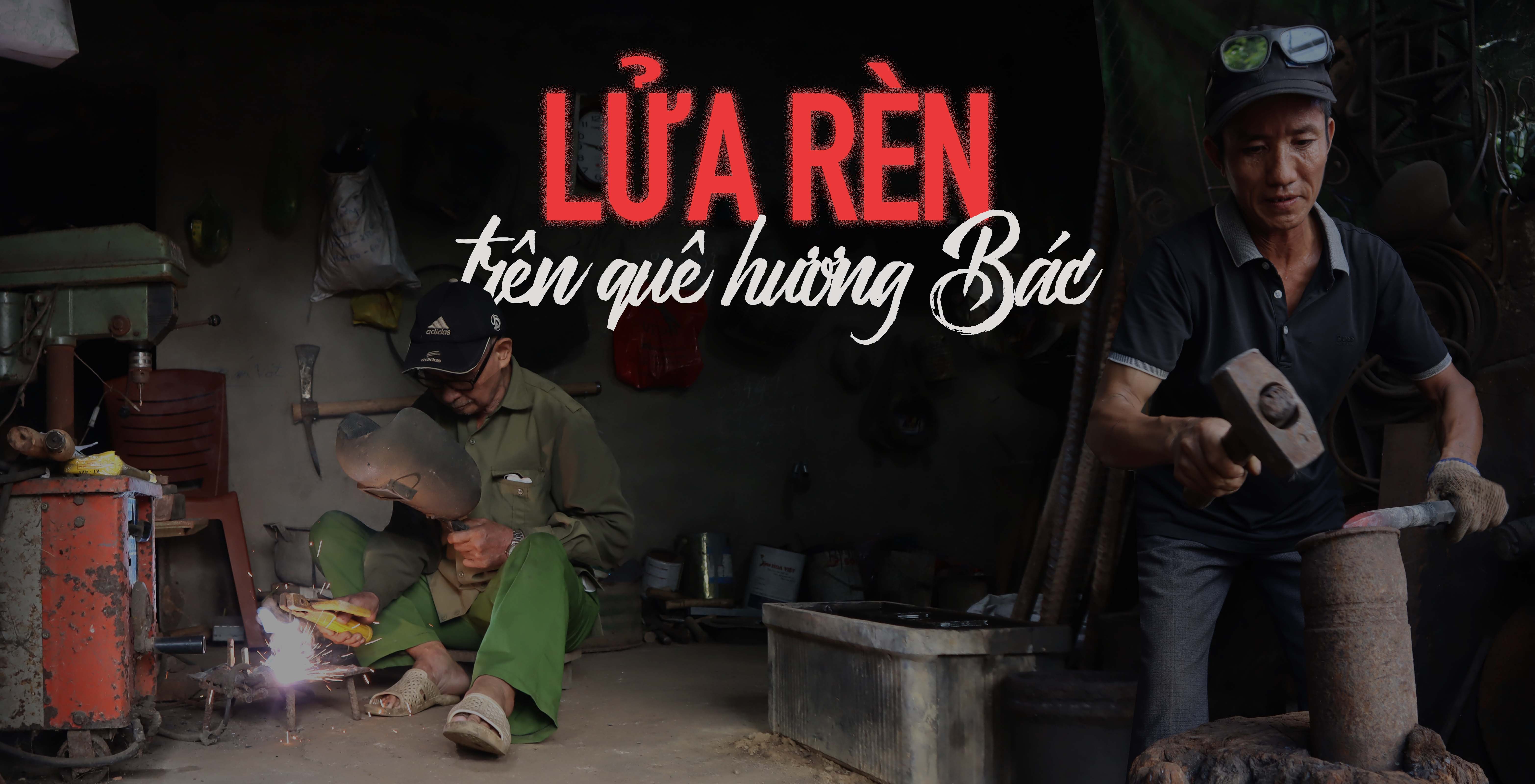

Forged in Uncle Ho's homeland

In Lien Son hamlet, Kim Lien commune, Nam Dan district - where the blacksmithing profession used to be very developed, now only a few households are still attached to the profession. That attachment is like a thread connecting the values of the past and present and the fire of the forge is like the love of labor, flickering for many years.

In Lien Son hamlet, Kim Lien commune, Nam Dan district - where the blacksmithing profession used to be very developed, now only a few households are still attached to the profession. That attachment is like a thread connecting the values of the past and present and the fire of the forge is like the love of labor, flickering for many years.

"PASSION" FOR THE PROFESSION

I visited Vo Van Hieu’s (born in 1979) forge on a scorching May afternoon. Although my back was drenched in sweat from the summer heat, I still felt that the temperature was “cool” compared to the temperature inside the space.blacksmith shopMr. Hieu's. Almost every corner of the workshop radiates heat, whether from coal or electricity, welding or grinding machines. To endure the heat of the forge all year round, Mr. Hieu's passion for his job must be higher than all else.

Mr. Hieu’s blacksmith shop mainly produces agricultural tools such as sickles, knives, hoes, plows, and vegetable cutting knives for livestock. It is harvest season, so people have a high demand for sickles, so the shop has a lot of these items. To complete a sickle, it takes him on average 1.5 to 2 hours with many steps.

First, you have to choose the material to make it, cut it into pieces according to the appropriate shape. Then, heat it red to soften it, use a hammer to adjust the shape to the correct tilt and bevel. Next, grind the sickle to get the desired sharpness and cut the spokes for the sickle. Finally, temper the sickle by heating it to the right temperature in a charcoal oven, dipping it in water and grinding it smooth again. A complete sickle is sold for 25,000 VND.

Mr. Vo Van Hieu

Of all the steps Hieu listed, cutting the spokes and tempering the sickle was probably the most skill-intensive. After just a few minutes of turning on the charcoal stove to heat the sickle to a red hot temperature, Hieu’s sweat was already streaming down his face, his tanned skin was even darker. Not only was it hot, the coal dust blown up from the stove was also very suffocating.

The blacksmith workshops in Kim Lien now no longer have the bellows and rotary kilns, but are replaced by blowers and many modern machines. The old blacksmiths have passed on their generations. But there are still some elderly people who are dedicated and committed to the profession.

About 400m from Mr. Hieu's house is the blacksmith workshop of Mr. Tran Dinh Thuc (born in 1941). At his rare old age, Mr. Thuc's blacksmith workshop still burns every day and is a prestigious address for the people in the area.Skilland Mr. Thuc's passion for the profession is high enough that customers from near and far can proactively come to his house to order without having to go to the market or sell to any store.

In addition to health and skills, blacksmithing also requires a strong mentality. For me, each stage requires time. It takes time to get the temperature right, to sharpen the knife, to temper it to the right degree… If customers keep standing next to me and urging me, I will not accept the job.”

Mr. Tran Dinh Thuc

It is not difficult to confirm his mental stability. His face is calm as if nothing happened amidst the harsh, ear-splitting sounds of the 30kg anvil, amidst the sweltering heat and the flames that were about to flare up in the furnace. Mr. Thuc's prestige is also shown in his meticulousness and carefulness in choosing materials to make and his excellent steel tempering skills by looking at the color of the steel. Mr. Thuc's products usually have a durability of 10-20 years, or even more. That is why each product he sells is many times more expensive than the market price.

In the special working environment of a blacksmith shop, no matter how skillful and careful the workers are, they will have the probability of encountering occupational accidents. For them, cuts, bleeding, and burns are completely normal. Their hands are therefore calloused and cracked over time, the skin on their hands thickening as a special identifying feature.

With health, experience, skillful hands, keen eyes and perseverance, the blacksmith workshop of Mr. Thuc and Mr. Hieu has provided iron and steel farming tools to the people around the area for many years. Although it is dirty and hard, they still love and want to stick with the profession for a long time.

CONTINUING OLD VALUES

In the past, Kim Lien commune had so many blacksmiths that a cooperative was established. Most of them were students of the late Dien and the late Tieng - characters associated with Uncle Ho's childhood. As society developed, the number of blacksmiths gradually decreased. Will the fire of the blacksmith furnace still burn forever?

Following his father to work as a blacksmith since he was 12 years old, when he was old enough to join the army, Mr. Thuc joined the resistance war. In 1977, when he returned to his hometown, he returned to his grandfather's and father's blacksmith shop.

My grandfather was an apprentice blacksmith from Mr. Dien. He passed it on to my father, who in turn passed it on to me. I love my job very much and will continue to do it until I can no longer do it. It is just a pity that none of my sons follow in my footsteps as a blacksmith…

Mr. Tran Dinh Thuc

With none of his children following in his footsteps, Mr. Thuc decided to pass on his skills to those who were willing to learn. For many years, he has trained many apprentices, each taking 3 months to master all the skills. Before parting, he always gave his students a set of tools to wish them good luck. His most successful student is now the owner of a famous blacksmith shop at Tho Son intersection (Tan Ky).

Also thinking of preserving the blacksmith profession, Mr. Hieu confided: “I don’t remember exactly when I became attached to the blacksmith profession. I only know that I spent my childhood years around the blacksmith furnace. Then, I helped my father forge and grew up to become a blacksmith like my father. For me, blacksmithing is both a way to make a living and to continue and preserve it.”

The value that Mr. Hieu mentioned is the new products that are suitable for customers’ needs, in addition to the traditional products. These are rice rakes, straw rakes, vegetable cutting molds for livestock farming… These products are produced by him with high perfection, reasonable prices, and sold wholesale to many stores in the wholesale market.