Mercedes-Benz turns Hungary into European production hub

Faced with slowing demand for electric vehicles and rising costs, Mercedes-Benz is restructuring its production network, investing heavily to turn its Hungarian factory into a strategic stronghold.

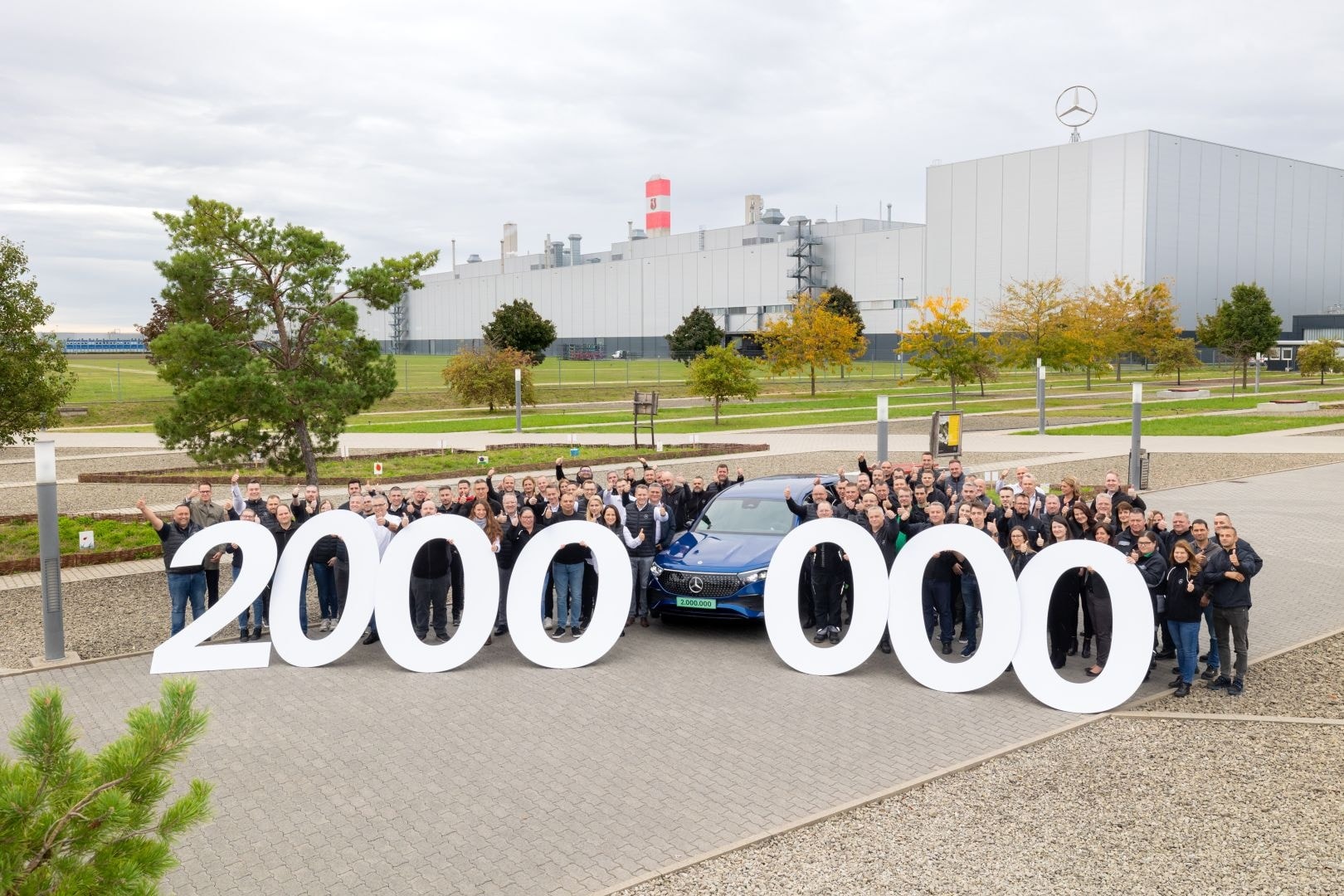

Kecskemét: The new production heart of Mercedes-Benz

The Mercedes-Benz plant in Kecskemét, which opened in 2012, is preparing for a major overhaul. With a total investment of up to 2 billion euros, the German carmaker plans to nearly double the size of the factory. The decision, announced after a meeting between CEO Ola Källenius and Hungarian Prime Minister Viktor Orbán at the beginning of the year, promises to create around 3,000 new jobs, bringing the total number of employees here to more than 7,500.

According to Mr. Jörg Burzer, Production Director, the new factory system is designed in a standardized module form, allowing each module to reach a capacity of 150,000 vehicles per year. When completed, the capacity at Kecskemét can reach 300,000 to 400,000 vehicles per year, surpassing single factories in Germany such as Sindelfingen, Rastatt or Bremen. This will increase the production proportion of Hungary in the total production of Mercedes-Benz cars in Europe to 30%, double the current level.

Reallocate strategic product portfolio

The expansion in Hungary is accompanied by a restructuring of the product portfolio. The Kecskemét plant will take on the production of two strategic models in the future. The first model is the pure electric version of the C-Class, developed on the MB.EA platform, which is expected to start rolling off the line in the second quarter of 2026. This will be followed by the new generation of the GLB SUV, including hybrid and pure electric options (new EQB).

Meanwhile, production of the next-generation CLA and CLA Shooting Brake will be moved to the factory in Rastatt, Germany. The Sindelfingen plant, also in Germany, will start building the all-electric version of the Mercedes-AMG GT high-performance car from next year. This model is considered a "revival" of the SLS AMG Electric Drive supercar, which is an icon for both the Mercedes-Benz brand and the AMG division.

"Next Level Performance" program and cost calculation

The move to Hungary is a key part of the “Next Level Performance” program, which aims to cut operating costs by 5 billion euros ($5.3 billion) a year by 2027. Chief financial officer Harald Wilhelm said the 2 billion euro investment in new models and factory restructuring is expected to save the company about 10% of production costs in the long term.

To achieve this goal, Mercedes-Benz has also implemented austerity measures in Germany, including temporary workforce cuts and voluntary redundancies for around 40,000 development and administrative employees. The company has set aside 560 million euros for severance payments in the first half of 2025 alone.

In parallel with the cost-cutting, Mercedes-Benz is preparing for a large-scale product launch phase in the next two years, including an upgraded S-Class, an electric E-Class and a much-anticipated electric compact G-Class.

Hungary: New stronghold of the European auto industry

Increased investment by Mercedes-Benz has cemented Hungary’s position as an increasingly important European automotive manufacturing hub. The country has attracted a number of major manufacturers, creating a vibrant industrial ecosystem. BMW Group is building its Neue Klasse plant in Debrecen, Audi AG has been present in Gyor since 1993, and notably, China’s BYD has chosen Szeged to produce the Dolphin Surf for the European market from late 2025.

Hungarian Foreign Minister Peter Szijjarto said that when the new Mercedes-Benz plant is operational, the country's total car production will reach one million units per year. This is a significant milestone, placing Hungary among the top five European car-producing countries and confirming its leading position in the global industry.

Overall, Mercedes-Benz’s decision to bet on Hungary is a strategic response to market fluctuations. By concentrating production of its strategic electric and hybrid models in a cost-effective hub, the German automaker is not only looking to protect its margins, but also to increase its flexibility to compete in an increasingly fierce electrification race.