Chiron is the successor to the Veyron - the legend that brought Bugatti into a new era and redefined several concepts in the automotive industry.

Bugatti officially launched the Chiron at the 2016 Geneva Motor Show in Switzerland, promising it would be the most powerful, fastest, most luxurious and rarest sports car in the world.

This supercar is assembled at Bugatti's Atelier factory in Molsheim, Alsace, France - the company's headquarters since its founding in 1909.

|

| The Chiron has a carbon fiber monocoque body, with a torsional stiffness of 50,000 Nm/degree. That's the same stiffness as an LMP1 car, or three times higher than a traditional steel structure. |

|

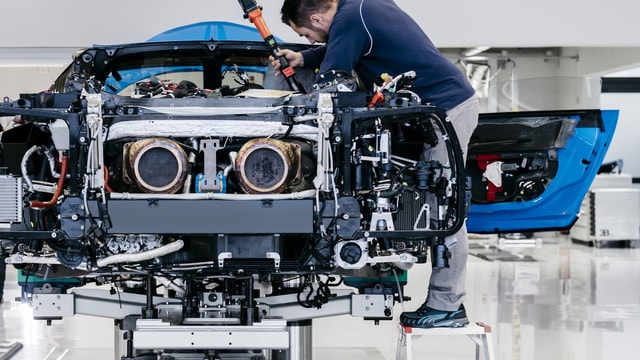

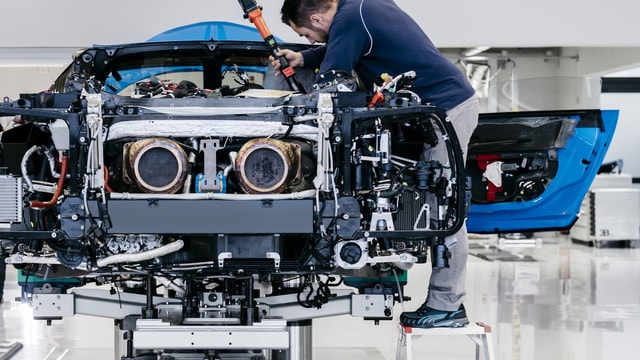

| 20 highly skilled workers will assemble more than 1,800 parts to create a Chiron supercar inside a clean factory area of more than 1,000 square meters. |

|

| The 8.0L W16 engine previously used in the Veyron has been redesigned, with four larger turbochargers, for at least 1,180 lb-ft of torque at 2,000-6,000 rpm, enough to accelerate the Chiron from 0-100 km/h in less than 2.5 seconds; another 4 seconds to reach 200 km/h and 11 seconds to reach 300 km/h. |

|

| The Bugatti Chiron supercar must go through a total of 12 assembly and finishing stages, without using conveyor belts or robots. |

|

| The engine was shipped from the engine plant of Volkswagen - Bugatti's parent company - in Salzgitter, Germany. |

|

| The Chiron's standard equipment includes 23 exterior paint colors, 8 carbon fiber material combinations, 31 different leather colors, 8 Alcantara synthetic leather colors, along with 30 stitching colors, 18 carpet colors and 11 seat belt colors. |

|

| To satisfy more demanding and sophisticated customers, Bugatti also offers thousands of different color combinations, along with other design options, such as attaching logos or initials of the car owner's name... on the rear spoiler, headrests... |

|

| Like with the Veyron, Bugatti chose Michelin as the tire supplier for the Chiron, with the product being 285/30 R20 for the front wheels and 355/25 R21 for the rear wheels. |

|

| The high-drag zones around the wheels are kept to a minimum. Three air vents on each side of the car are used to cool the brakes. |

|

| Given the Chiron’s immense power and torque, the test rig in Molsheim, France, had to be reworked. “We built it for the Veyron, but the torque of the Chiron was so great that we had to rework the test rig,” said Christophe Piochon, Bugatti’s head of production and operations. |

|

| Before the car is carefully polished and protected in preparation for delivery to the customer, in addition to nearly 60 km of mechanical testing, each Chiron is driven an additional 350 km of real roads, including mountain roads in the area. Acceleration tests (up to 250 km/h) and braking tests are conducted on the motorway near Colmar airport. |

|

| This year, only a maximum of 70 Bugatti Chirons will be produced, and the first will be delivered to customers in the first quarter of this year. |

|

| Not everyone who has the money can buy a Bugatti Chiron, one of the most expensive cars in the world. Customers usually have to wait 9 months from the time they place an order to receive the car. |

According to Dantri