Nghe An farmers turn waste into clean energy

(Baonghean.vn) - Currently, not only large livestock farms but also many farms and households in the province have developed a livestock model according to the garden-pond-barn-biogas model to help reduce input materials, save living expenses, and especially limit environmental pollution.

We visited the family of Ms. Hoang Thi Thuy (Xuan Thanh hamlet, Phong Thinh commune, Thanh Chuong district) on a rainy day. Working as a rice paper maker, on days when there is no sun to dry the rice paper, Ms. Thuy has to use a gas stove to dry and press the rice paper. Therefore, a lot of gas is consumed, plus cooking for the family.

Ms. Thuy said: “Every month if it rains, there will be a lot of rice paper, and cooking will use up about 1.5-2 industrial gas cylinders, about 1 million VND. That’s not to mention cooking rice and boiling water, which all use electricity. The gas bill each month also accounts for a large amount of expenses.”

Since February 2023, she has built a biogas tank, using animal waste to produce gas. Accordingly, with a scale of raising 15 pigs and 1 buffalo, the amount of waste discharged is very large. Previously, it was only used to fertilize plants and fields, but it was not used up, and it overflowed into the garden, causing a lot of pollution.

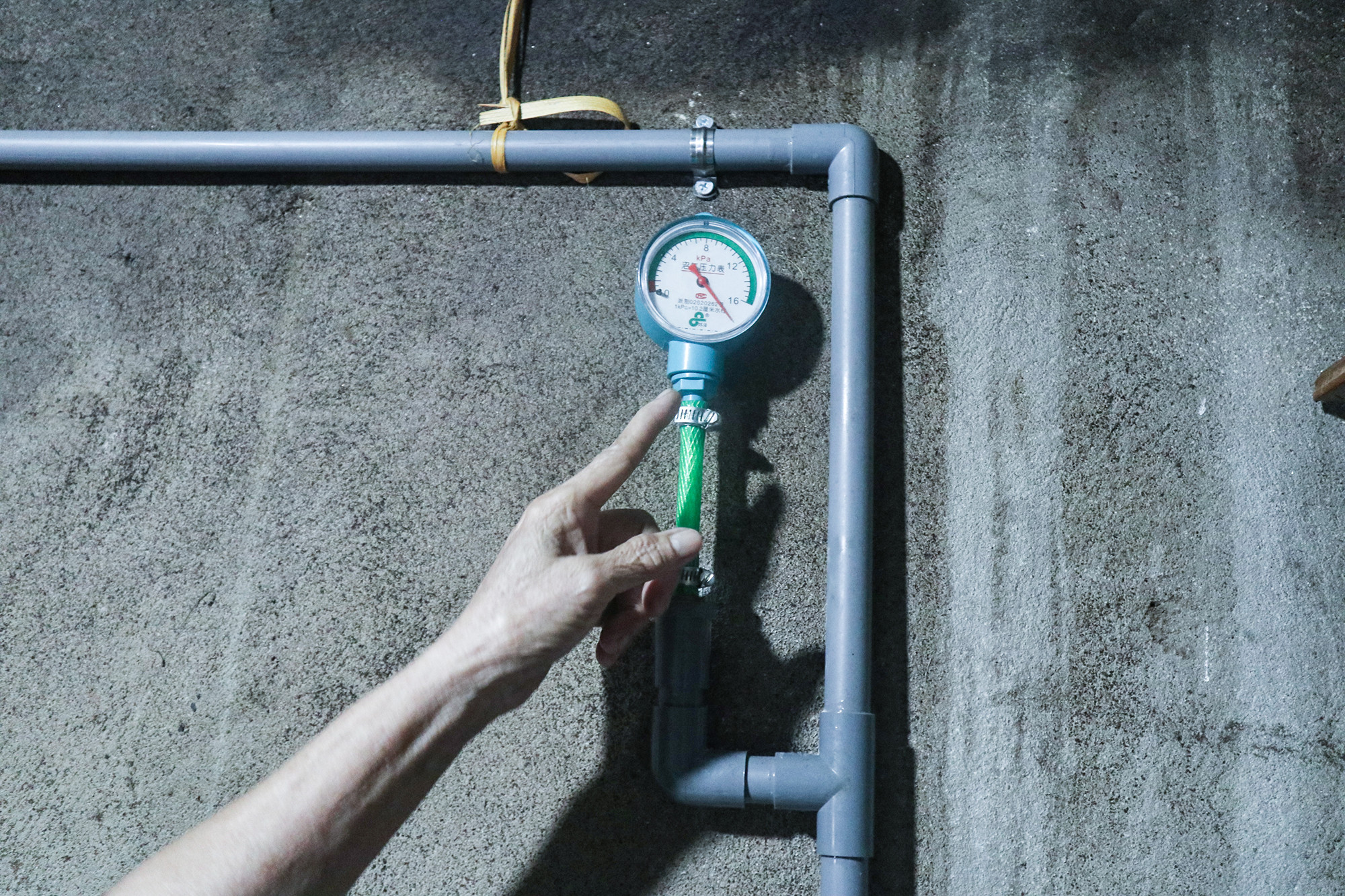

“It stinks, flies and mosquitoes, so it is very polluted. Farmers, without livestock, will not have “income and output”, and with livestock, the problem of waste treatment is very difficult. Since building a 10m biogas tank3, all waste is processed into gas, waste residue is fermented into organic fertilizer, wastewater is clear, odorless, used to water plants. The pollution problem is completely solved, there is still excess gas for baking and cooking," said Ms. Thuy.

From the effectiveness of her family, Ms. Thuy and her siblings contributed money to build a biogas tank for her parents. “My grandparents raised 30 pigs, and the waste discharged daily was so large that the neighbors complained. Seeing the “double” effectiveness of using a biogas tank to treat livestock waste, my grandparents have now installed one,” Ms. Thuy shared.

Ms. Hoang Thi Mao's family in Lien Chung hamlet (Phong Thinh commune, Thanh Chuong district) lives on a steep hill, with a rather limited area, and the livestock pens are adjacent to houses and wells, so raising pigs and chickens faces many difficulties. "The main thing is that we don't know how to handle livestock waste. Raising a small amount is not worth the effort and there is no profit, raising a large amount is pollution," Ms. Mao said.

So, when there was a project for a biogas tank, her family immediately registered to build it; the cost to build the tank, gas pipes, stove... was about 10 million VND. "The initial capital may be a bit high, but it almost completely solves the bad smell and stench in livestock farming, and has a source of excess fuel for cooking, saving 500,000-700,000 VND per month," Ms. Mao added.

One of the pioneering families in building biogas tanks in Thanh Hoa commune (Thanh Chuong) is Mr. Nguyen Trong Dung's family (Dong Hoa hamlet). Being a purely agricultural family, raising livestock is the main source of income. Although living far from residential areas, they determined that if they expanded and multiplied their herds, it would be difficult to keep the environment clean, affecting the health of family members. Therefore, his family chose to build a biogas tank to solve environmental problems in livestock farming. For the past two years, Mr. Dung's family has not had to buy industrial gas for cooking, saving 5-7 million VND per year on gas.

In the process of building new rural areas, one of the difficulties in localities is environmental criteria. The model of processing livestock waste into clean energy is bringing double benefits, both protecting the environment and increasing income for people.

Mr. Tran Van Ky - Chairman of the Farmers' Association of Phong Thinh Commune said: "Previously, environmental pollution in livestock farming in residential areas was always a "hot" issue, mentioned in voter contact sessions. In the past two years, in the commune, there have been many models using biogas tanks to treat livestock waste. Not only large-scale livestock households, but also small-scale households with 3-5 pigs can build tanks to treat waste into gas."

From the environmental protection efficiency that biogas pits bring, Thanh Hoa commune (Thanh Chuong) has issued a resolution directing the replication of the model, at the same time, allocating funds to support 10 households to implement, in order to encourage people to use biogas pits to treat waste in livestock farming, protecting the rural environment.

The whole province currently has nearly 800,000 buffaloes and cows, nearly 1 million pigs and 34 million poultry. If farmers only care about the main products and ignore by-products, the amount of emissions will lead to pollution, affecting the living environment. Realizing that, not only large farms but also many households in the province have developed a model of raising livestock according to the garden-pond-barn-biogas model, which reduces input materials, saves living expenses, and especially limits environmental pollution.

However, the current model of treating livestock waste into fuel is still difficult to replicate due to the high initial investment cost; in addition, people's awareness is still limited, they think that gas produced from waste is not as clean as industrial gas.

In fact, with the current number of livestock raised by families, the daily surplus of gas is quite large, if not used up, it will be discharged, which is very wasteful. Therefore, it is necessary to pay attention to research so that this gas can be connected to the hot water tank system or 2-3 households can share the gas line to use, which will be much more effective.

When using a biogas tank, the following requirements must be met: the source of manure and water used must not be mixed with chemicals; the waste must be fed regularly every day; the residue on the pressure floor must be cleaned every 6 months; the residue in the gas tank must be cleaned every 5 years and the tank must be cleaned every 10 years. When an incident occurs, there must be inspection and guidance from technical staff.