How is the 'Made by Vietnam' satellite being assembled to be launched?

The MicroDragon satellite has been completed in every small detail and tested to ensure high precision, ready for launch on January 17.

|

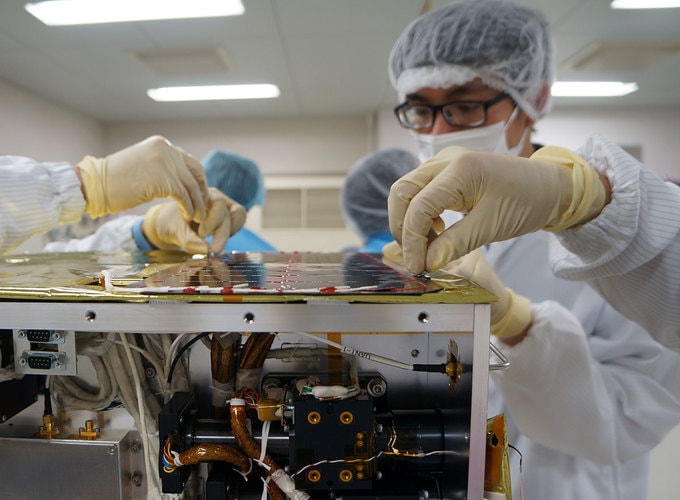

| With the guidance of leading Japanese experts, 36 engineers of the Vietnam Space Center participated in designing, manufacturing and testing the MicroDragon satellite (50 kg). |

|

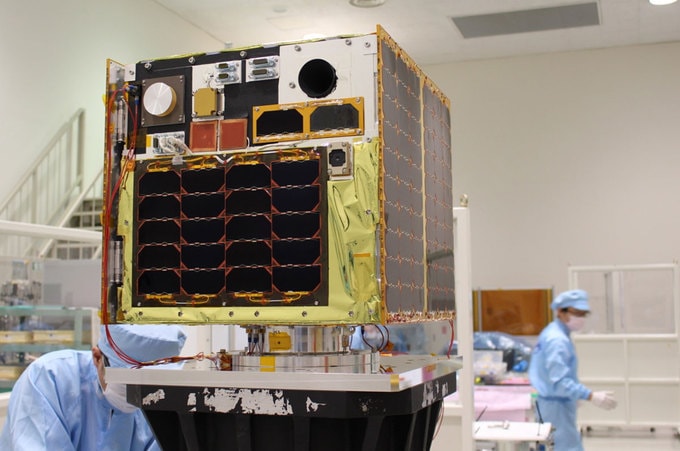

| The main mission block of MicroDragon satellite uses a system of 2 multispectral cameras with adjustable liquid crystal filters (LCTF) that can capture in 2 spectral bands, visible light (wavelength from 412 nm to 740 nm) and near-infrared (wavelength from 730 nm to 1026 nm), the best ground resolution image is 78 m, the image size is about 36×48 km when the satellite operates in an orbit of 511 km. |

|

| Every detail such as: Earth magnetic field sensor, momentum wheel, solar sensor, position sensor, S-band transceiver, S-band splitter... are all carefully and meticulously assembled to ensure high precision. |

|

| Each part of the satellite has its own mission to serve the research and observation of coastal waters to assess water quality, locate aquatic resources, and monitor changes in phenomena occurring in coastal waters to serve the Vietnamese aquaculture industry. |

|

| After 4 years (2013 - 2017), engineers participated in training programs and directly designed and assembled the MicroDragon satellite, which was completed and put into final vibration testing before launch. |

|

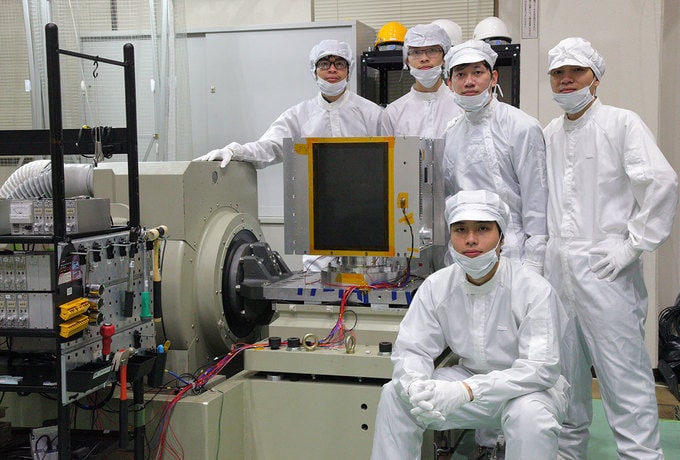

| This is the control screen when testing the satellite to check and monitor the operating parameters of the system. |

|

| A group of young Vietnamese engineers with the MicroDragon satellite product. They are waiting for the historic moment (7:50 am - Hanoi time, January 17), when the MicroDragon satellite will fly into orbit to carry out the tasks that have been built. |