Making car parts from carbon in the air

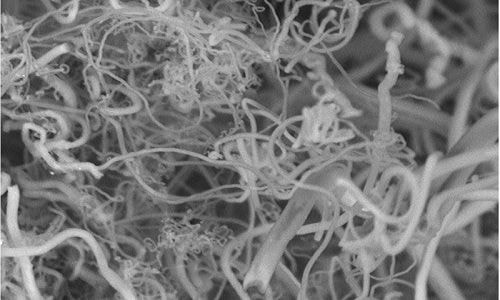

Carbon in the air can be spun into tiny nanofibers, a raw material used to make strong compounds in aircraft components, gym equipment and sports cars.

|

| Carbon nanofibers are used in the manufacture of aircraft, fitness equipment and sports cars. Photo: Stuart Licht. |

A research team led by Professor Stuart Licht at George Washington University in Washington, DC, USA, has designed a process to capture carbon from the air and turn it into a product that is worth much more than the cost of production. The research results were announced at a conference of the American Chemical Society held earlier this week in Boston, Massachusetts.

According to the research team's calculations, carbon nanofibers cost $25,000 per ton, but with this process, the production cost is only about $1,000.

The process takes place in an electrolytic cell, where carbon mixed with air is dissolved and piped into a tank containing lithium carbonate, a common industrial chemical. The carbon nanofibers then form into thin strands resembling steel, growing from tiny pieces of nickel, cobalt, or copper.

Recently, the team increased the current used to grow carbon nanofibers from 1 to 100 A. The current can come from conventional sources, but Licht has also successfully harnessed solar energy.

If scaled up, the process could also help combat climate change. “We calculate that with a land area less than 10 percent the size of the Sahara Desert, our process could capture CO2 and return atmospheric carbon levels to pre-industrial levels within 10 years,” Licht says.

According to VnExpress