Horrified to see the steps of making ham and sausage

Using cheap raw materials, poor food hygiene and safety, along with additives and chemicals of unknown origin, is harmful to consumers' health, which is happening at some ham and sausage production facilities in Quang Trung commune, An Canh district (Hung Yen).

|

Pieces of meat lay piled up on the dirty floor.

Dirty everywhere

In the role of the person ordering ham for the wedding, we went to the private ham factory of Mr. Nguyen Van B's family, which specializes in producing, wholesaling and retailing ham for many years in Quang Trung commune, An Canh district (Hung Yen). After a while of hesitation to "pre-emptively" test the strange guest's intentions, but before our earnest attitude, Mr. B finally opened up more.

Starting with the usual brand promotion refrain, the ham owner introduced himself: "Every party in the commune who orders from my house, everyone praises the ham as rich, crispy, delicious, and fragrant. From the time the goods are made until the funeral is finished, the ham can be left for 2 more days without worrying about the smell... If you order more than 50kg, I only charge for the ingredients, not the labor..."

Going around the factory, the first thing that caught our eyes was the piles of red meat lying on the dirty white tiled floor, lard, frozen ground pork, banana leaves used to wrap pork, salt, fish sauce, MSG scattered everywhere, with flies and mosquitoes swarming around that no one bothered to chase away.

Using the excuse of waiting for the cashier to come and make the transaction and receive the goods, we chose a corner to sit and observe. In the hot sun of the beginning of the season, in the workshop, about 3-4 young men and women were sweating profusely, cutting lean meat, fat meat, weighing the right amount and putting it into the grinder... continuously working.

Mr. B is the one operating the machine, the rest of them do not follow any production line, each person is in charge of all the steps from slicing meat, measuring fish sauce and salt additives, wrapping ham, shaping sausage, crushing ice..., even shoveling coal into the furnace to boil the ham.

|

Cheap raw materials are packed tightly in the refrigerator and are combined with each meat grinder according to the "secret" ratio of the manufacturer.

It seems that the hired ham makers are so used to customers coming to inquire and place orders that they are still busy with their work. They only give brief answers when we ask about ingredients, additives, and how to make ham because today they have to deliver nearly 100kg of ham to 4 parties in the commune.

At this time, a young man driving a Dream motorbike rushed straight to the door, threw two sacks of pork down, then quickly spread them out on the floor and turned on the fan to point directly at the pork pieces. When wondering why the pork was not washed but put into the grinder, Mr. B laughed happily, pointed at the meat pieces and analyzed in detail: "The first rule of making sausage is not to wash the meat, if it gets wet with saliva, the meat will die and must be thrown away because it cannot be ground into sausage. Even touching a piece of meat that is slightly hot makes it difficult to grind, so when the meat comes home, you have to spread it all out and turn on the fan to prevent it from dying."

According to Mr. B's principle above, after collecting meat from the slaughterhouse, the regular customers at the market must cut it into small pieces and put it all into the grinder to mix with lard and additives immediately. A ham mortar of this factory needs 3kg of lean pork, 200g of fat and additives (fish sauce, MSG, salt...) to produce up to 15kg of ham. When making sausage, the amount of fat is slightly higher - 500g of fat, 3kg of meat always comes with lard and additives, there is no such thing as lean meat, different lean - fat ratios will have different prices. After grinding, the ingredients are poured into a stainless steel tray to wrap the sausage and shape the sausage.

Looking at banana leaves - the material used to wrap the spring rolls, we could not help but be horrified. The leaves were torn into bundles and were still left on the floor. Turning a bundle over, we saw that many of the leaves were dirty, the dead ants and white cocoons that had made nests on the leaves were brushed away by the workers with their hands. If they were not handy, they would use their bare feet to drag around the house and yard, the dirt would get on the leaves, and some people would even quickly use a piece of rag left on the wet, black, dirty and smelly floor to wipe...

|

Identify the "magic" additive that helps make ham crispy, delicious, and last longer...

Knives, cutting boards, and meat grinders are placed on shelves when finished without needing to be cleaned... According to T - a young person who has been working at the factory for nearly a year: "Knives and grinders are only cleaned once in a while to avoid them becoming dull, rusty, and quickly broken". The large refrigerator is not much better at preserving ingredients as it is dirty from the outside in. Piles of pork, pork skin, flabby fat, and frozen ham that are not clearly moldy or still fresh are packed tightly in the refrigerator.

An employee here revealed: "Those are all cheap, leftover ingredients that are stored away. Every day, we add more ingredients to the mortar and add more additives, which will not affect the quality of the ham and sausage, but only by using them like that can we hope to make a little more profit. If we keep using fresh meat and good fat, which are currently priced at 90-100 thousand VND/kg, and expensive additives, we will only be serving the public, where will we make a profit?"

Ham and sausage… “immersed” in chemical additives

At another ham factory in Quang Trung commune, we encountered a scene similar to that of Mr. B's factory. Through investigation, Mr. Le V. T (ham worker) said: "Additives and chemicals for making ham include salt, sugar, MSG, fish sauce and anti-mold chemicals, creating tough, crispy, fragrant ham, which can be kept for a long time. There are also additives to prevent the ham from swelling while boiling, giving the ham an attractive pink color, and coloring agents for the ham... But indispensable are still fish sauce, MSG and chemicals to create toughness, crispness, and to keep it for a long time."

|

Sugar, MSG small, white, unusually smooth.

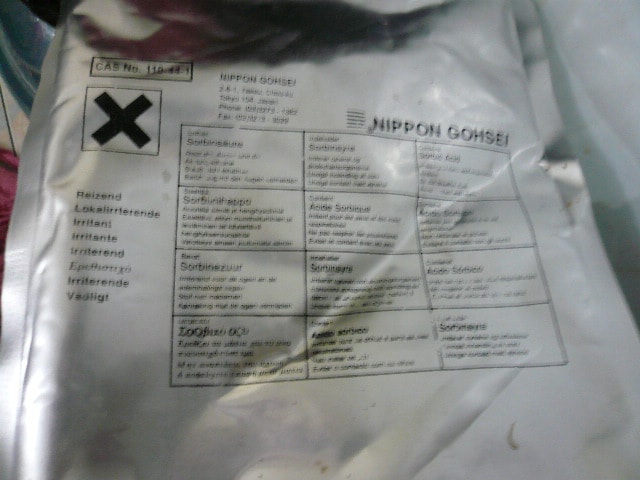

According to the natural answer of the owners of the sausage factory, "before, we used borax, but now many customers order without borax, so we don't use it anymore and use other chemicals instead. This type is "high quality", it's a very expensive Japanese product, so it's very safe. The sausages are crispy, delicious, and have an impeccable pork aroma" (?!).

Taking advantage of the time when the boss was busy delivering goods to another wedding, the young employee leaned close to my ear and whispered: “This type of chemical is not sold in Hung Yen, the boss had to ask an acquaintance to buy it from Hanoi and send it by bus, MSG and a few additives with foreign names were also bought there in large sacks. As for additives and chemicals, either the boss, the boss's wife or their cousins would bring them back themselves, they would never ask a worker to get them.”

Following his hasty toss, I noticed the “high-end, very expensive” spices placed inside, close to one corner of the refrigerator. Both of the white sacks had no product information, the only distinguishing feature was on the outside of the sack, marked with a few capital letters scribbled in marker: SUGAR, MSG. “To avoid confusion for workers when taking them,” another worker explained. The health hazard was that these products, when touched, were all small, smooth, unusually white, and had a stronger flavor than the spices commonly used by consumers. All were put into a blender and blended together with the “artisan”’s own secret recipe to produce hundreds of kilograms of ham and sausage of all kinds every day.

“This type of chemical is not sold in Hung Yen, the boss had to ask an acquaintance to buy it from Hanoi and send it back by bus. MSG and some additives with foreign names were also bought there in large sacks. As for additives and chemicals, either the boss, his wife or his cousins would bring them back themselves, and he would never ask a worker to get them.”

According to Labor