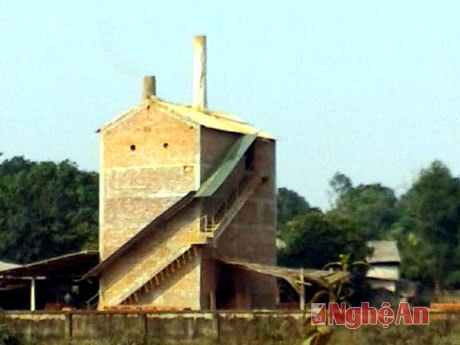

Energy-saving brick production model

(Baonghean) - Currently, when manual brick kilns cause quite heavy pollution to the living environment, and modern tunnel brick kilns have construction costs too high for households, the emergence of vertical continuous brick kiln technology is an effective solution to save energy, limit environmental pollution, and bring high benefits to brick production businesses.

In 2010, to continue maintaining the brick making profession, Mr. Nguyen Tat Vien's family, Nghia Son block (Phu Thoi Ward, Thai Hoa Town) boldly went to the Northern provinces to learn about brick production using new technology. From there, Mr. Vien decided to borrow capital to invest and build a VSBK vertical continuous brick kiln to improve the family economy, creating jobs for dozens of local workers.

Vertical continuous brick kiln is an effective measure to save fuel, overcome environmental pollution, production scale and investment capital suitable for households or small and medium enterprises. The product is a project of the Institute of Thermal and Refrigeration Technology under Hanoi University of Science and Technology. Initially, the vertical continuous brick kiln only produced solid bricks, but now it has produced radial-hole bricks with a porosity of 25% - 30% and tubular bricks with a porosity of up to 50%, very suitable for the needs of localities in Thai Hoa town.

|

| Vertical brick kiln technology. |

The kiln consists of two layers of walls, including: the inner brick chamber wall and the outer wall of the kiln. The distance between the two walls is 1m, which will be filled with cheap insulation (slag, soil mixed with rice husks). The kiln has a large or small cross-section depending on the design of the production household. Each kiln is arranged in many batches, each batch consists of 4 layers of bricks, and the firing time for each batch is about 5 - 6 hours. When operating, the combustion mode in the firing zone is adjusted in the middle of the kiln and maintains a temperature of about 9000C. Above the firing zone is the heating zone, and next is the drying zone. Smoke coming out of the firing zone will pass through the heating zone and the drying zone before being discharged outside. The temperature of the smoke coming out is low, about 700C to 1300C, so it does not affect the outside environment. Below the firing zone is the cooling zone. When the bricks are ripe and have enough time, they are gradually moved to the bottom of the kiln and are slowly cooled. Cold air is supplied from the bottom of the kiln, when passing through the newly fired brick layer, it will make the bricks cool down gradually, at the same time the air is heated before being supplied to the firing area. Because the stages of placing bricks in the kiln, drying, heating, firing are not interrupted like manual brick kilns, so fuel consumption is reduced, fully utilized, so the amount of smoke emitted is very little.

According to calculations, this brick kiln has the advantage of saving fuel from 45% - 60% compared to manual kilns. The exhaust gas flow is reduced by 11.5 times, the amount of SO2 CO2 is reduced by 6 times, the exhaust gas temperature is low, and the number of workers is reduced by half compared to manual kilns. Productivity and quality of bricks are significantly improved, and the bricks are fired more evenly.

Because of these outstanding advantages compared to manual brick kilns, Mr. Vien's family has worked hard to learn, invest in construction, and apply this brick production technology. This is also the first new type of brick kiln to appear in Quang Phong ward, as well as Thai Hoa town. Mr. Nguyen Tat Vien - Owner of the new technology brick kiln VSBK said: "Since the decision to abolish manual brick kilns, my family has strictly complied but is also very worried. Because I still really want to do this brick production job. So my family has consulted new technology brick kilns in converted areas such as Hanoi, Thai Binh, Ninh Binh... From there, I have invested in building a VSBK vertical continuous brick kiln to produce bricks and I see that the brick kiln brings higher economic efficiency than manual brick kilns. Not only that, this new type of brick kiln produces good quality products and does not pollute the environment"...

Up to now, after nearly 3 years of conversion, Mr. Vien's family's new technology brick kiln has been in stable production with a capacity of more than 3 million bricks per year. Applying this brick kiln production model has helped his family save energy, leading to higher profits than production using old manual technology. In addition, because it does not emit smoke like manual brick kiln production, environmental factors are always guaranteed. This has also created peace of mind for workers participating in the brick kiln.

Mr. Nguyen Canh Kieu, Chairman of Quang Phong Ward People's Committee, Thai Hoa Town, said: In the ward, Mr. Nguyen Tat Vien's family is the first household to convert to the new continuous vertical kiln technology VSBK. After more than 2 years of continuous production, the kiln has also been inspected by the authorities and the town's Department of Natural Resources and Environment to have no impact or pollution to the environment. The new kiln has brought high economic efficiency and good quality bricks. This is the brick kiln model that we will replicate in the ward.

It can be said that brick production using new technology is very superior. However, due to the large investment cost, a new brick production line costs about 2 billion VND, so it will be difficult for brick producers with little capital. Therefore, to replicate the vertical continuous brick kiln model, the government and authorities at all levels need more attention in supporting and giving preferential loans to households and businesses that are capable of implementing brick production using new technology.

Thu Hang(Thai Hoa Radio)