What is Japan doing to revive the semiconductor chip industry?

With the ambition to return Japan to being a semiconductor powerhouse, Prime Minister Shigeru Ishiba has decided to provide a support package of about 65 billion USD until fiscal year 2030.

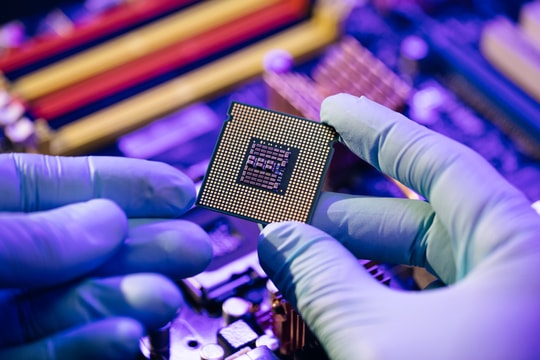

The funding is part of a national strategy to rebuild Japan’s once-proud semiconductor industry. The government is actively supporting the Rapidus joint venture, a key project that aims to build modern chip factories that can compete with the world’s leading technology powers.

At the same time, Japan is also actively attracting international chip manufacturers to invest in the country, aiming to diversify the supply chain and reduce dependence on external sources.

.jpg)

“We will establish a new support framework to attract more than $325 billion in public and private investment over the next 10 years,” Mr. Ishiba said, stressing that this would be part of a larger effort to “rebuild” Japan.

The plan will be part of a comprehensive economic package expected to be finalized in November, funded through subsidies, investments from government institutions and debt guarantees, local media reported.

The move comes as Japan is actively strengthening and diversifying its semiconductor supply chain, with the government aiming to triple sales of domestically produced chips to more than $97.5 billion by 2030.

Support domestic semiconductor chip companies to develop

One of the beneficiaries of the funding announced on November 11 is Rapidus, a Japan-based chipmaker, a government-backed venture that is a key part of the country’s chip industry revitalization strategy. Rapidus is at the center of Japan’s efforts to boost domestic chip production and increase competitiveness in the global semiconductor sector.

Established in 2022 with direct support from the Japanese government, Rapidus is a strategic joint venture to promote the domestic chip industry. The company has strong backing from many major Japanese corporations, including Toyota Motor and Sony Group, leading companies in the industrial and technology sectors. In addition, Rapidus has partnered with IBM, a leading US technology corporation, to leverage advanced technology and international expertise.

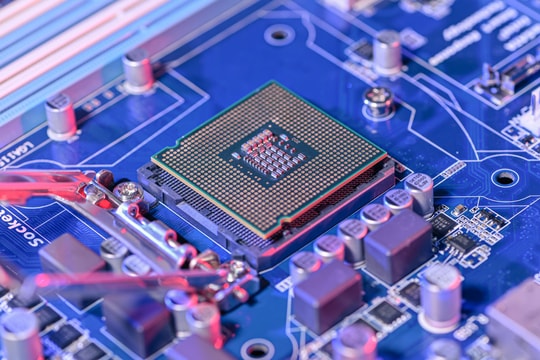

The company has received more than $2 billion in financial support from the Japanese government, with the specific goal of achieving mass production of advanced 2-nanometer logic chips by 2027. This funding will not only help Rapidus invest in modern technology and infrastructure, but also strengthen its research and development capabilities, ensuring that Japan can compete with the world's leading chipmakers.

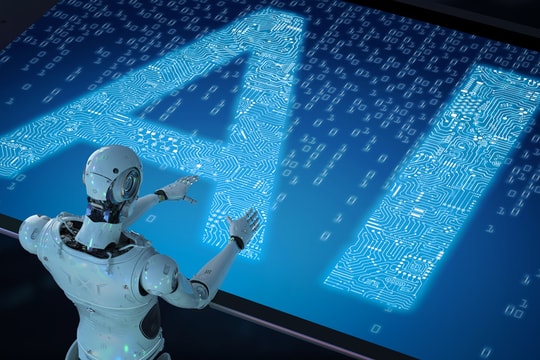

Logic chips are specialized chips used to process information and perform tasks in electronic devices. The most advanced logic chips today are widely used in modern technologies such as artificial intelligence, quantum computing, and machine learning, where powerful computing capabilities and high processing speeds are required.

Rapidus President Tetsuro Higash called the company “the last chance” for Japan to regain its leadership in the global semiconductor industry. He said it was a crucial effort for Japan to catch up with pioneering nations in the field, such as Taiwan and South Korea, as the semiconductor industry plays an increasingly important role in the global economy and technological security.

In the 1980s, Japan was the leader in the chip manufacturing industry, accounting for more than half of the global semiconductor market. During this period, Japanese companies such as NEC, Toshiba and Hitachi dominated the semiconductor industry, with their chips widely used in electronic devices, computers and other technological products.

However, the country began to lose its lead with the emergence of foreign competitors such as Taiwan Semiconductor Manufacturing Co. (TSMC), now the world's largest contract chipmaker, and South Korea's Samsung.

Both Samsung and TSMC, two giants in the semiconductor industry, have announced detailed plans to start commercial production of 2-nanometer chips by 2025. With large investments in research, development and factory construction, both companies are aiming to create advanced logic chips with higher performance, lower power consumption and more compact size.

Meanwhile, the US has established itself as one of the most important centers in the global chip design field, led by leading technology companies such as Intel and Micron. These companies not only pioneer the development of advanced chip designs but also play a role in providing the foundational technology for modern industries.

At the same time, the Netherlands has become a leader in the production of the world's most advanced chip manufacturing equipment, thanks to the company ASML. ASML is the exclusive supplier of EUV (Extreme Ultraviolet Lithography) lithography, a revolutionary technology that enables the production of extremely small and high-performance chips, laying the foundation for the rapid development of the global semiconductor industry.

Attracting investment from the world's leading semiconductor companies

In addition to the goal of building a leading chip maker in Japan, the subsidies are also designed to attract the return of world-leading companies that have taken over or acquired key Japanese chip businesses in the past, part of an overall strategy to restore Japan’s position in the global semiconductor industry.

The government hopes that providing financial support and incentives will not only stimulate domestic investment but also encourage multinational companies to bring back advanced technology, management experience and production networks, thereby promoting sustainable development for the domestic chip industry.

With support from the Japanese government, chipmakers such as TSMC, Samsung Electronics and Intel Corp. have agreed to invest billions of dollars in Japan. These companies are leaders in making memory chips used to store data, essential in data centers used for artificial intelligence and cloud computing.

The world's largest contract semiconductor chipmaker TSMC has announced plans to build a second manufacturing plant in Japan before completing its first.

Attracting such companies to Japan could help the country quickly promote vertical integration across the entire supply chain and build its semiconductor ecosystem faster, according to Brady Wang, a semiconductor analyst at Counterpoint Research.

Japan has also signed cooperation agreements with allies such as the US, UK, Taiwan and several EU countries aimed at promoting research and development related to next-generation semiconductors.

Is Japan's strategy feasible?

Michael Yang, senior director of semiconductors at analytics and consulting firm Omdia, told CNBC that while Japan has lost its lead in semiconductor manufacturing and fabrication, the country still maintains a leading position in a number of key areas. Specifically, Japan is now the global leader in essential semiconductor materials and equipment, such as silicon wafers, process chemicals and high-tech manufacturing tools.

These sectors not only play a core role in the semiconductor supply chain but are also crucial to the performance and quality of advanced chips, helping Japan maintain a strategic position in the global semiconductor industry despite increasingly fierce competition.

Through subsidies for the chip industry, which are mainly aimed at increasing production capacity, the country will be able to expand into other aspects of the semiconductor supply chain and enhance its strategic position in the global semiconductor market, Mr. Yang added.

However, Brady Wang of Counterpoint Research said that Japan's recapture of the chip industry's market share will be a big challenge. According to him, Rapidus will have to find "shortcuts" in the chip design and manufacturing process to be able to achieve the same level of advancement as the world's leading semiconductor companies.

Rapidus representatives said the architecture of 2-nanometer chips is different from 3-nanometer chips, making mass production of these chips “a completely new challenge for all companies” and opening up great opportunities to penetrate the market.

However, in this effort, "subsidies are a must, but cannot guarantee success," Wang said, adding that it took TSMC more than a decade to catch up with global chip companies and build relationships with customers.

"Subsidies are just a basic requirement to enter the semiconductor industry, but success requires more supporting measures, such as talent, technology and strategic planning," said Ken Kuo, senior vice president of research at technology market research firm TrendForce.