Spirulina production in Quynh Luu: New model with high economic efficiency

(Baonghean) - In recent years, Spirulina algae has received attention from consumers due to its many nutritional values that are good for...

(Baonghean) - In recent years, Spirulina algae has been of interest to consumers due to its many nutritional values that are good for human health. The protein content in Spirulina is the highest of all current foods (accounting for 56-77%), the vitamin content is extremely rich, trace elements such as K, Mg, Fe, Mn, Zn are also very high, beneficial for the functioning of the nervous system and cardiovascular system, anti-aging, preventing cancer and stimulating the body's immune response to harmful agents from the outside...

Therefore, Spirulina has been considered a functional food, a healthy food and has been industrially cultivated and widely used in many countries, led by Mexico, the US, Japan, Taiwan, etc. in many different forms of preparations with an output of hundreds of tons in each country per year.

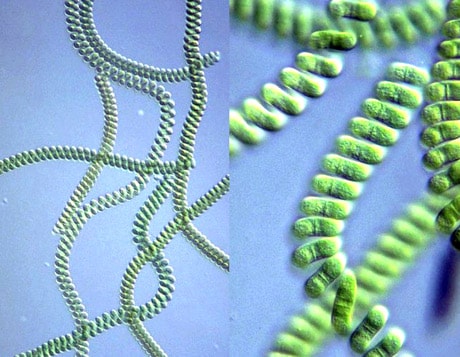

Spirulina algae. Photo: PV

In our country, products extracted from spirulina are still very few, the imported rate accounts for over 70% and the price is still expensive. Currently, a number of facilities have been established to cultivate and produce products from spirulina, mainly concentrated in the southern provinces such as Binh Thuan, Dong Nai... Meanwhile, the North and Central regions, which are considered to have great potential in algae cultivation, the market is still left open.

Grasping information about the great value, as well as the demand for Spirulina algae in the country and the world, the model of cultivating and producing Spirulina algae of Mrs. Tran Thi Thao, Hamlet 6, Quynh Luong, Quynh Luu was born, has researched and successfully built the process of cultivating and producing Spirulina algae on the poor agricultural land of Quynh Luong.

This Spirulina farming model is not too complicated, including a cement or alkali-resistant cement concrete pond, a greenhouse-style roof, and a green fence around the pond to prevent dust and other contamination. With this process, the harvested algae are immediately put into the extraction process. Dried Spirulina is packaged and preserved to be used as a medicinal ingredient.

The time to raise a batch continuously lasts about 90-120 days, the time to harvest a batch is 8-15 days. The incubation process until the product is produced includes the following steps: After being propagated in the level 1 seed room, the algae are cared for under a strict regime that continuously maintains a source of oxygen and light for 3-5 days, then released to the level 2 seed room at the appropriate ratio, developing for about 5-7 days, the level 2 seeds are released to the outdoor tank. When the algae are released into the tank, it is necessary to minimize external contamination such as wind, dust, insects, etc. At the same time, the pH concentration of the algae must be checked regularly, and the chemical analysis of the concentration ratio of trace elements must be checked to have the most suitable development.

To produce Spirulina algae products, production must ensure the correct process, especially strict requirements on environmental hygiene. The conditions for producing algae seeds require sterilization, the culture bottles and equipment must be strictly sterilized by steaming and drying. If subjective or careless in any step, the algae will be infected with bacteria, dirt, or foreign algae and will not be able to grow.

In addition to its beneficial effects on human health, the secondary products of Spirulina are also used as very good food for other types of aquaculture such as shrimp, crab, clam, oyster, etc., which is favorable for the development of coastal aquaculture. Thanks to that, it creates more jobs and improves people's lives. In addition, the secondary products of Spirulina also provide a source of nutritious food for livestock and poultry, creating conditions for sustainable livestock development and are a source of organic fertilizer for green vegetables, limiting the use of inorganic fertilizers and pesticides.

With this Spirulina cultivation technology, clean Spirulina products are produced stably and economically, continuously harvesting many generations of Spirulina after one breeding. Currently, this cultivation model has been applied with an outdoor farming scale of about 5000m2. On average, 1 hectare of Spirulina microorganism production can harvest 5 tons of algae powder/year, reaching a value of 5 billion VND (1kg of algae powder costs 1 million VND, while currently, agricultural farmers only commonly achieve 30-50 million VND/year/ha).

Ms. Thao said that in the coming time, she will expand the scale of spirulina production on an area of 1-2 hectares, enhance production technology and equipment, enrich algae products, meet the growing demand of consumers not only domestically but also towards exporting to markets in the region and the world.

It can be said that the direction of cultivating and producing spirulina is a new and positive direction that first appeared in Nghe An and the Central region. Spirulina production in the direction of biotechnology has created products with high economic value, creating jobs and increasing income for local people. The valuable thing is that workers have gradually learned to approach technology, apply scientific and technical advances to the production process to create products with high nutritional value, contributing to improving the quality of life of people as well as opening up new opportunities for local economic development.

Tran Hoa (Center for Science, Technology and Informatics Information)