0% import tax: Will Toyota leave Vietnam?

After many years, Vietnam's supporting industry, especially the supporting industry serving the automobile industry, has remained stagnant. Mr. Kyohei Hosono, General Director of Dream Incubator Vietnam, shared with NCĐT his views on the development strategy of this industry.

|

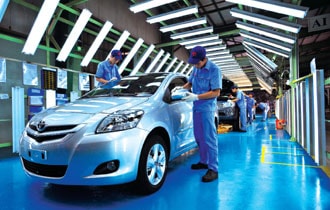

Import tax on completely built-up cars will be reduced to 0% in 2018 and Toyota may leave Vietnam in the next few years. This is no longer a guess but a possibility confirmed by Toyota's management. This is due to the ASEAN free trade agreement called AFTA.

In Vietnam, to protect the auto industry, a 60% tax has been applied to imported cars from the ASEAN region. For example, a Lexus has an import price of about 2 billion VND and a price after tax of 3.2 billion VND. If registration fee and some other fees are included, the final price can be up to about 4 billion VND.

However, according to AFTA, import tax on completely built-up vehicles will be 0% in 2018. This new tax rate will have a strong impact on the domestic automobile manufacturing industry. The reason is that in Vietnam, the domestic production rate of high-value auto parts is very low. Parts that can be produced in Vietnam are mainly simple spare parts such as seat belts, seats, wiring harnesses, etc. The remaining important equipment with high technology content must be imported. There are differences depending on each car manufacturer, but in general, the domestic production rate is only about 20-30%. Thus, when the import tax on completely built-up vehicles is 0%, importing spare parts and assembling in Vietnam will obviously be more expensive than importing completely built-up vehicles from Thailand or Indonesia.

The low localization rate is a testament to the weakness of the supporting industry serving the automobile industry. This is also the common situation of many industries in Vietnam. Samsung Electronics (Korea) has a modern smartphone factory in Vietnam and this is the company's largest factory in the world. Samsung's export value in 2013 is expected to be about 23.8 billion USD, accounting for about 15% of Vietnam's total export value.

However, according to information from Samsung, almost all equipment and components used for phone production must be imported. The factory in Vietnam has the main function of assembly to take advantage of cheap labor. Obviously, the current production process in Vietnam does not create much added value.

Therefore, the Vietnamese Government needs to soon propose measures to promote the development of the supporting industry. The first important thing to do is to expand domestic demand.

An example is the motorbike market in Vietnam. Honda has more than 3 million vehicles sold annually. Of which, more than 75% of the car company's spare parts are produced domestically. That has created a nearly complete value supply chain. Meanwhile, the domestic car market in Vietnam is still very small. The total number of new cars sold in 2012 was less than 90,000, only 1/15 of the consumption in Thailand.

The main reason lies in the lack of consistency in Vietnam's development policies. On the one hand, the government wants to develop the auto industry, but on the other hand, it has policies that restrain consumption demand. For example, the government decided to increase the registration fee by nearly 10 times in 2012. As a result, the domestic auto industry faced an unprecedented storm of declining sales that year.

It is true that Vietnam’s current transport infrastructure is still weak, affecting the demand for automobiles. Traffic congestion in big cities is something no one wants. Sometimes it takes an hour to travel a short distance, not unlike Bangkok. However, if the Government is determined to act with a long-term strategic vision, expanding domestic market demand along with improving transport infrastructure development is not impossible.

Along with expanding domestic demand, incentives are needed to attract some large companies in the early stages, thereby creating a pull to call on other companies to join to form a complete supply chain. One of the most effective measures is special tax incentives for supporting industries.

Consider the case of Thailand. In the past, Thailand applied a policy of 8-year corporate income tax exemption for some industries to attract investment. The country also implemented a number of other policies to make Thailand become the Detroit of Asia in 2003. Thanks to that, Thailand has attracted 14 of the world's largest car manufacturers, 7 motorcycle manufacturers and 2,350 manufacturers of supporting parts for cars and motorcycles. The localization rate of this industry reached 80-90% in 2010. The right development strategy, at the right time and at the right level has made Thailand the largest car manufacturing center in Southeast Asia and ranked 9th in the top car manufacturing countries.

In fact, developing supporting industries is a common challenge for all emerging economies. However, for Vietnam, the challenge is even greater due to the timing factor. Indonesia and Thailand went through this stage many decades ago. At that time, there was no free trade mechanism like AFTA. Therefore, the trade protection policy with tariff barriers that these countries built supported the development of domestic manufacturers of components and spare parts.

Vietnam is in a completely different situation. In the next few years, when tariff barriers within the ASEAN region are eliminated, Vietnam's manufacturing industry will be threatened and opportunities for supporting industries will be further narrowed.

Developing supporting industries to be on par with Thailand and Indonesia in the next 5 years is difficult. However, to protect a large consumer market with a population of more than 90 million people, Vietnam needs a long-term strategy to support supporting industries, including the automobile supporting industry. Only then can the risk of Toyota leaving Vietnam be eliminated.

If Toyota withdraws from Vietnam, there will be significant consequences. It is not simply the loss of a long-standing technical production base, but it also creates a negative image of Vietnam's competitive position and investment environment to the international community.

The strategy to develop supporting industries is becoming more urgent as Vietnam is gradually losing its advantage of cheap labor in labor-intensive industries compared to some other Asian countries, especially Myanmar. This Southeast Asian country is implementing strong political and economic reforms and is a threat to Vietnam.

The average salary of a factory worker in Vietnam is about $200 a month, while in Myanmar it is just under $100 a month. Currently, large, labor-intensive garment factories such as Nike (USA) and Uniqlo (Japan) have factories in Vietnam because of cheap labor costs. But these manufacturers are now planning to move their factories to Myanmar to take advantage of lower labor costs.

Although this shift is not happening immediately, it is clear that Vietnam is losing its competitive advantage in highly labor-intensive industries. To deal with this threat, Vietnam needs a long-term strategy to build and develop supporting industries to retain foreign investors and bring high added value to the economy.

According to nhipcaudautu