Unknown stories about the stone pressing steel weaving profession

(Baonghean.vn) - Starting from a household, the craft of weaving stone gabions has quietly developed into a hamlet, a village in Hung Chinh commune (Vinh city). Under the skillful and flexible hands of the craftsmen, the steel wires like silk threads and bamboo threads are woven into shapes and blocks in a miraculous way.

Steel weaving village

Present at the steel warehouse opposite Dong Vinh gas station (Vinh City), I was really impressed with the image of many steel rotating frames rotating at the same time under the control of workers. The frame is a creation in the labor process of stone cage weavers. The structure of this rotating frame device is not too complicated. With 2 round molds that can flexibly adjust the size and a bearing system on the shaft, the frame operates entirely by human power, just like the silk reeling frames in silk weaving villages. The difference is that the steel rotating frames are placed horizontally instead of standing vertically, the steel fibers are thicker, harder and a thousand times heavier.

| Performed by: Diep Thanh |

While rotating the steel, Mr. Nguyen Quoc Hung - an elderly person in the group of workers, introduced: "In the past, when there was no such rotating shaft, workers had to rotate it by hand, each rotation required at least 3 people at 3 corners, which was extremely hard and time-consuming. Now, only one person can do it, and it is also fast and accurate."

According to the workers, when working with steel, situations such as steel being stuck in the legs or hooked in the hands are normal and everyone has experienced them. “In addition, workers need to wear masks to limit the risk of steel dust flying into the eyes and nose. The process of rotating, dismantling and knitting steel will shoot out a lot of tiny dust that is difficult to see with the naked eye,” said Nguyen Ngoc Tu, a young worker.

|

| Workers weaving baskets spin the amount of steel corresponding to the number of baskets they receive from the factory. Photo: Diep Thanh |

From the steel rings that are rotated to the correct sample size, the workers use iron scissors to cut them into sections and fold them into a semicircle, weigh the corresponding quantity of the products to be woven, load them onto motorbikes, and take them home. At home, before being woven, these semicircular curved steels also have another step of straightening. Because all the steps of preparing and producing the gabions are done entirely by human power with supporting equipment, the gabions can be considered a handmade product. And when witnessing the nimble hands of weaving steel, the workers are just like real artisans.

|

| Almost all stages of basket weaving are done by human power. Photo: Diep Thanh |

In the village of stone gabion weaving, if you want to know which house is doing this job, you just need to look at the yard and you will immediately recognize it. In the corner of the yard are always bundles of steel and steel rolls ready-made. The yard surface has round holes drilled into it to insert iron stakes to make a weaving frame. Among those who do stone gabion weaving, Mrs. Tran Thi Ha and her husband, Mr. Tran Quoc Cuong, are considered the most skillful and diligent workers. While her husband straightens the steel bars, Mrs. Ha wears gloves, inserts stakes according to the frame size and uses thick steel to pull the frame. After completing the frame, she fixes the smaller steel wires at the pre-marked distance on the floor and begins to weave the wires together. This wire hooks onto that wire, this corner folds into that corner, Mrs. Ha's two hands control the steel wires so nimbly and quickly that if you just look at it, it will be difficult to know how she did it, so flexible that from a distance, people think she is weaving bamboo or rope. In a squatting position, the worker's arms stretch out to where the mesh holes are formed.

While knitting, Mrs. Ha said: “When we first started this profession, around 2010 or so, our yard wasn’t big enough so my husband and I decided to chisel the steps. The newly curved brick steps were full of holes, and everyone felt sorry and blamed us. But only by chiseling can we do the job, and only by doing the job can we make money.”

|

| Mr. Cuong and Mrs. Ha weave baskets on the porch. Photo: Diep Thanh |

Talking about his job, Mr. Cuong continued his wife's story: "When you first start working, you will have numb legs, back pain, and neck pain because of squatting a lot and carrying heavy loads. Your hands, not used to bending steel, will ache so much that they will fall off. But after a while, you will get used to your hands and work, and you will feel strong. You can knit all day, even on days when there are many orders, you can knit until 1-2 am and still feel strong."

“During times when there were many orders, every household in the village kept their lamps on all night long to weave baskets. The workshop was bustling with people coming and going to spin steel. When the trucks arrived at dawn, people would call each other to load and unload. It was so much fun!” – Mrs. Tran Thi Ha recalled.

|

Necessary equipment when weaving baskets is a pair of protective gloves to protect your hands and a pair of sandals as thick as possible to step on the steel. Photo: Diep Thanh |

To weave a complete stone gabion consisting of 6 sides of a 2x1x0.5 cube according to the model that Mr. Cuong and Mrs. Ha are weaving, it will take about 30-45 minutes, equivalent to 20 thousand VND in labor. With smaller or thicker mesh models, the weaving time will be longer, and the labor will also be higher. The income is not much, even just taking the labor as profit, but it has helped his family and many other families in the village have an additional source of income to cover their lives.

Grateful for the gabion

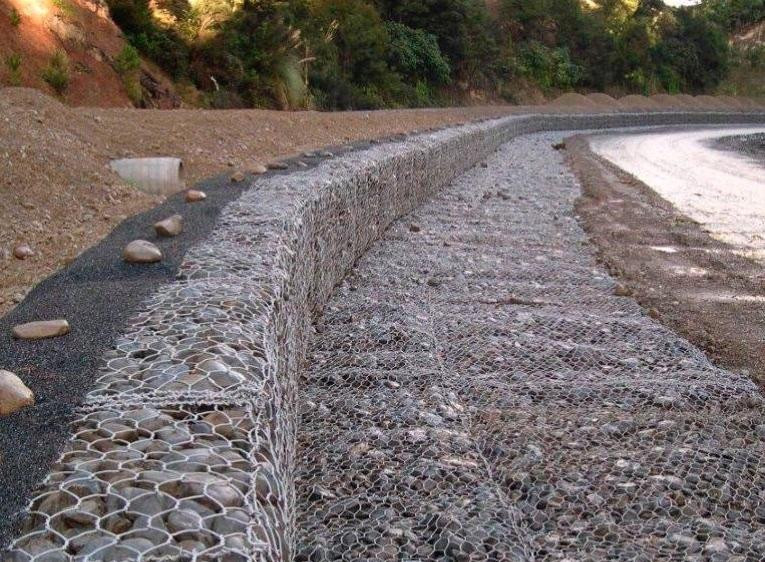

As one of the technical products used very popularly in construction works related to geology, gabions are often woven with steel, used to hold rocks, compress rocks, creating solid blocks. With high applicability, gabions are often used in works to protect canal banks, embankments, dams, and make retaining walls toanti-erosion,erosion, soil reinforcement, road and railway protection...

|

Since the Covid-19 pandemic, the number of workers at Mr. Sinh and Mrs. Lich's stone cage workshop has decreased significantly. Photo: Diep Thanh |

In Dong Vinh, the first people to initiate the production of this product were Mr. Nguyen Truong Sinh and Mrs. Nguyen Thi Kim Lich. Originally workers of the Railway Materials Company, after retiring early, seeing the opportunity from producing stone cages for construction projects, Mrs. Lich and her husband decided to produce stone cages to earn more income. Working while studying, producing on a small scale at home, the couple did not intend to establish a business but only made enough to supply to construction material stores around the area. Later, because the products were beautiful, the prices were good, many customers proactively came to order directly and needed documents and invoices, so the couple reluctantly had to open a company.

Sharing about the gabion product, Ms. Lich said: “Gabions are usually produced in cubes with dimensions of 2x1x1m or 2x1x0.5m. Unlike concrete, gabions woven from steel have high elasticity and drainage, allowing the movement of natural groundwater, over time mud will fill the gaps of the gabions, helping the development of the flora and balancing the ecological environment.”

|

A construction project using stone cages in Dong Vinh ward. Photo: NVCC |

The most developed period of the stone basket weaving profession was from 2010 to 2018, when special attention was paid to the construction of works and traffic infrastructure. In response to the increasing demand of customers, Mr. Sinh and Mrs. Lich instructed villagers on how to weave baskets and placed them in the market.manufactureat home. At first, only the elderly, former workers of the railway material company participated, later also the elderly and young people. Even in the summer, middle and high school students also followed their parents to help with the work to supplement the family income.

“We ourselves feel happy because we can provide them with jobs and opportunities to earn money to support their lives. Since the pandemic, construction projects have been stagnant, goods are in stock, and there are many outstanding orders. The workshop has no orders, and workers in the village have had to find other jobs. Up to now, the whole village has only 9-10 people still working. Hopefully this period will pass quickly, when everything is back to normal, the villagers will have more income from rock cages,” Ms. Lich confided.

.jpg)

.jpg)