3D printed ceramics for supersonic aircraft skin

With the ability to withstand temperatures up to 1,700 degrees Celsius, 3D printed ceramics are the perfect material for making new generation supersonic aircraft, rockets and spacecraft.

|

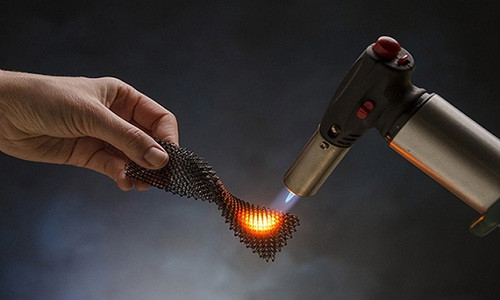

| 3D printed ceramics can withstand temperatures of 1,700 degrees Celsius. Photo: yibana. |

According to Discovery News, American scientists used 3D printers to create custom ceramic parts with super light weight, high durability, good insulation and less cracking. This result helps open a new generation of jet aircraft with bodies or engines made of ceramic materials, which can fly at supersonic speeds from New York to Tokyo in a few hours.

“If you go about 10 times the speed of sound in air, any vehicle will heat up due to friction,” said Tobias Schaedler, a senior research scientist at HRL Laboratories in Malibu, California. “If we want to build a vehicle that can travel at hypersonic speeds, its skin has to be made entirely of insulating ceramics.”

Making parts from ceramic materials is more difficult than plastics and metals because they cannot be cast or machined as easily. According to research published in the journal Science on January 1, Schaedler and colleagues invented a plastic formula that can be 3D printed into parts of any shape and size.

The shuttle used older-generation ceramic materials under its skin to insulate it during re-entry, but the ceramics were fragile and had to be replaced frequently. Photo: NASA.

“We create a printable ceramic precursor like a polymer, and once sintered, the polymer transforms into a ceramic,” Schaedler explains. “There is some shrinkage during sintering, but it is uniform so the design shape is very predictable.”

The printed plastic parts will be sintered, turning into a solid ceramic with high durability. This ceramic material can withstand temperatures up to 1,700 degrees Celsius and is 10 times more durable than other similar materials.

In more important applications, the new method allows the production of many special small parts of satellites and rockets, which are able to withstand the heat generated during friction with air at high speeds, as well as the high temperatures generated by exhaust gases during take-off.

"This method brings us closer to the goal of successfully manufacturing lighter, stronger materials in more complex shapes," commented Stefanie Tompkins, representative of the Defense Advanced Research Projects Agency under the US Department of Defense (DARPA).

According to VnExpress

| RELATED NEWS |

|---|