Cement and the problem of resource use

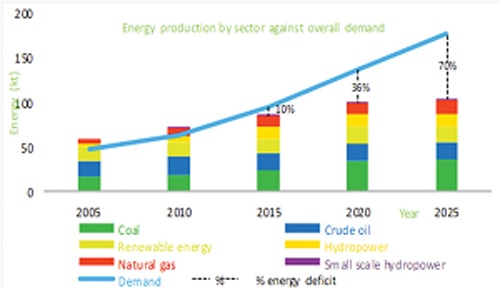

According to the National Power Development Plan report, Vietnam faces a shortage of about 10% of energy demand in 2015, which will increase to 70% in the next 10 years. From an energy exporting country, we are at risk of having to import and depend on energy, leading to increased investment costs.

|

| Illustration photo |

Holcim Vietnam understands that the success of its business depends largely on the efficient use of energy and natural resources. That is why we always set goals to reduce dependence on natural resources, manage natural resources sustainably and increase the use of alternative resources.

Reduce water consumption with clear water management directives and savings targets

Water is an essential resource for production at all Holcim plants worldwide. Although the water consumption of the construction materials industry is negligible compared to other industries, we are still aware of the challenges and our responsibility to protect this resource.

In 2013, the Holcim Board of Directors set a target of reducing water consumption per ton of product by 20% by 2020 (compared to 2012). Also in 2013, water consumption in the aggregates segment of the group decreased by 8%. This was achieved through improvements in input materials and water management systems.

Following the Group’s guidance, Holcim Vietnam has applied the Water Management Directive since 2013 to manage the use of water resources. The Directive applies to both actual water consumption and water loss at all plants to optimize water consumption in all activities.

Use alternative materials

Using waste as an alternative fuel and raw material is an important step in Holcim's Sustainability journey. This source of raw materials helps to limit the use of fossil fuels and reduce emissions to the environment.

By fully treating cement kiln waste, Holcim Vietnam can control the risk of rising energy costs, improve energy security and reduce the consumption of natural resources.

We set a clear target for thermal energy consumption by co-processing alternative fuels. According to Holcim's Sustainable Development ambition, by 2030 we will use 1 billion tonnes of secondary raw materials, replacing around 25% of the natural raw materials needed in production.

Energy consumption management

Over the years, many initiatives have helped Holcim Vietnam consume electricity efficiently, specifically: roller mills help reduce 20% of electricity consumption, power stations utilize waste heat energy to meet about 25% of the electricity demand of Hon Chong factory and build a culture of efficient energy use among employees...

According to Construction Newspaper

| RELATED NEWS |

|---|