'Innovation tree' of Nghe An garment industry

(Baonghean.vn) - Working and developing in a working environment that always honors and encourages training and creativity, Mr. Pham Van Kien - a member of the Trade Union of Minh Anh Garment Joint Stock Company (Do Luong) has strived to become a typical good worker.

From tailor to technology team leader

During 5 years working at Minh Anh Garment Joint Stock Company (Do Luong), Mr. Pham Van Kien - Head of Technology and Innovation Group has always researched and created many technical innovations, contributing to reducing costs and bringing high productivity in production.

Almost every morning, Mr. Pham Van Kien is always one of the first people to arrive at the company. Before starting his shift, he takes the time to check the work content of the day, assign tasks to each member of the team, and then starts working with everyone.

|

| Mr. Pham Van Kien is one of the typical creative workers of Minh Anh Do Luong Garment Joint Stock Company. Photo: Le Lai |

Born in 1989, in Dai Son commune, Do Luong district, after finishing high school, Mr. Kien stayed home to work in the fields. In 2015, after learning sewing, he started working at Minh Anh Kim Lien Garment Joint Stock Company. In 2017, he moved to work at Minh Anh Do Luong Garment Joint Stock Company.

Smart, diligent, hard-working, from a tailor, Mr. Kien was selected for training and then worked in the technology group, specializing in design and technical improvements in production. During his work, he always went down to the teams and workshops to grasp and listen to everyone's opinions, study the working process of the machines, from there to research, improve and overcome the shortcomings, limitations, to benefit the company.workersand company.

Currently, Mr. Kien and everyone in the group are focusing on researching and improving the stages of bag mounting, bag flap gluing and front body cross-stitching. Improving this stage not only helps workers save time, but also improves the quality and aesthetics of the products...

Not long ago, he himself also researched and improved the technology of kansai elastic banding, a step that other garment factories have to do manually, installing elastic banding on products by hand, which is very time-consuming and not aesthetically pleasing. Improving the technology of kansai elastic banding has helped shorten the time, reduce the number of workers, and the products are more beautiful and precise.

Ms. Nguyen Thi Hang in Sewing Group 6 said: Since the technology of stopping elastic with Kansai machine was applied, she and everyone here have had a lot less trouble, the products are completed quickly, evenly and beautifully.

During his 5 years working at the company, Mr. Pham Van Kien has had many initiatives and improvements in the production process such as: "2-in-1 iron fixture" for patching and edging quilted shirts, improving the "round raincoat pocket gluing" process using a "programming machine"; improving the rough sewing and turning of the front flap; improving the process of patching pockets, gluing pocket flaps, and patching the front flap horizontally...

In addition, he also participated in teams and groups, creating many other innovations with savings of up to hundreds of millions of VND; participating in the program "1 million initiatives - efforts to overcome difficulties, creativity, determination to win the Covid-19 pandemic" launched by the Vietnam General Confederation of Labor...

When asked about the secret to creativity, he humbly said: “To have good initiatives, you must always be passionate about your work, committed, consider the company as your home, from there ponder and think from the actual production to find out what is good and what is not, then from there invent and improve the features and uses of each machine. Every time I have an innovative initiative that is applied, I feel very happy because I have contributed to bringing convenience and productivity to workers, at the same time, bringing profit to the company.”

To achieve such remarkable achievements, few people know that Mr. Kien had to work very hard. His house is 12 km from the company, his family is in difficult circumstances, and he has to take care of a young child. Not everyone can simultaneously arrange family work and ensure his duties at the company like him.

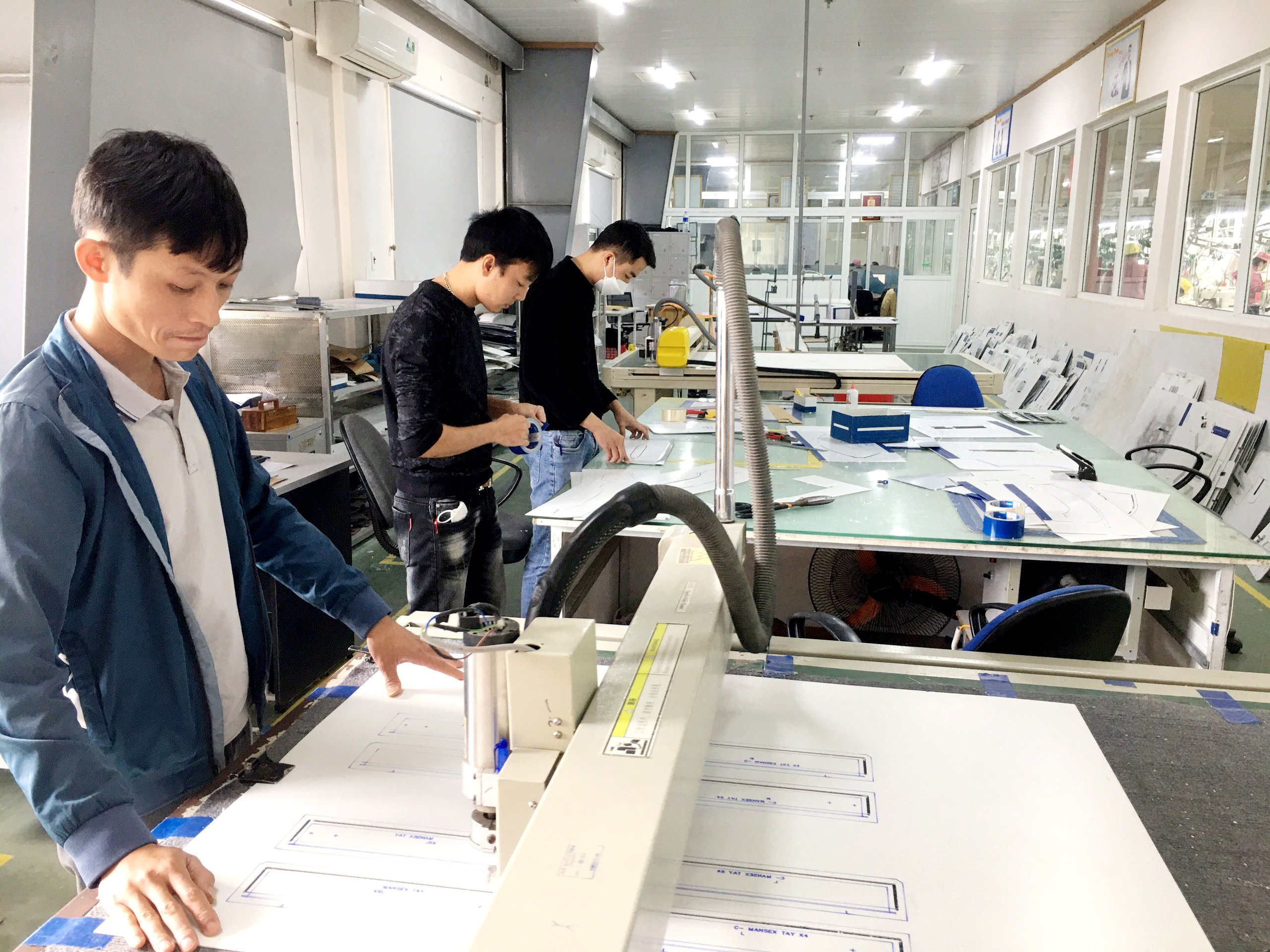

|

| Mr. Kien working with his colleagues. Photo: Le Lai |

Ms. Le Thi Ha - Chairman of the Trade Union of Minh Anh Do Luong Garment Joint Stock Company said: "Although he did not receive formal training, with his determination, intelligence, diligence in learning and researching, Mr. Pham Van Kien has researched and improved many stages in production, contributing to the great benefits of the company. In addition, he always actively participates in movements launched by the company and the trade union such as cultural and sports movements, volunteer movements..."

Loving the profession, always dedicated and creative in work, sociable, having a spirit of solidarity, helping everyone, every year, Mr. Pham Van Kien is commended and recognized by the company's leaders. In the last days of 2022, he has another great joy: He is one of 30 outstanding individuals to receive a Certificate of Merit from the Chairman of the Provincial People's Committee for "Having many achievements in labor and production in 2022", selected to attend the program "Workers' Festival - Welcome Spring Quy Mao 2023" organized by the Provincial Labor Federation on the occasion of "Tet Sum Vay 2023". With what he has done and is doing, he is completely worthy of this honor.

Building a “cradle” for creativity

Sharing the “secret” of creativity, Mr. Pham Van Kien further affirmed: “In work as well as in daily life, if you want to go further and faster, you must definitely try to learn from your colleagues and superiors. The achievements I have achieved are largely due to the fact that I have contributed to a collective that always honors creativity, encourages and motivates employees to strive and surpass themselves.”

|

| An internal training session of Minh Anh Do Luong Garment Joint Stock Company. Photo: CSCC |

Indeed, at Minh Anh Do Luong Garment Joint Stock Company, the movement of good workers, labor, and creativity is very interested and supported by the company's leaders and union. Ms. Le Thi Ha - Chairman of the Union of Minh Anh Do Luong Garment Joint Stock Company said: "The company in particular and the group in general regularly organizes skill improvement courses, skill competitions and is ready to create conditions for workers to learn more in the most impartial way. This movement has been built for many years and every year we find new factors to reward and honor. That creativity not only brings benefits to the business but also pride and opportunity for workers. Not only honored on the occasion of summary, holidays, Tet, workers are also praised and rewarded immediately at the time of completing the invention".

According to Ms. Ha, in the past 2 years, the company's Union has also organized the "I am number 1" contest to create a playground for union members and skilled workers. If labor and creativity honor union members with many inventions like Mr. Kien, the skill contest will honor hard-working, proficient, and highly productive workers.

|

| Workers enthusiastically compete in the contest "I am number 1". Photo: CSCC |

“Recognizing and honoring employees appropriately and promptly will motivate them to work harder and produce more. However, we still have to admit that this honor is just beginning to be widespread in the business sector.

In the coming time, the company's Trade Union will focus more on supporting workers in building profiles, participating in emulation and honor movements organized by the superior trade union and departments and branches. We hope to turn the factory into a "cradle" of creativity and love of work, so that every worker can become agood workers, creative workers" - Ms. Le Thi Ha shared more.