Song Lam Cement Joint Stock Company: Double benefits from excess gas thermal power generation

(Baonghean.vn) - The waste gas thermal power generation system is a new advanced European technology solution applied by many countries in industrial sectors. This technology is currently also applied and installed by The Vissai Cement Group in synchronization with the construction process of Do Luong Cement Factory (Nghe An) and has been in stable operation since 2016.

|

| Panorama of Song Lam Cement Factory in Do Luong. Photo: Nhat Minh |

The residual gas thermal power generation system operates based on the principle of collecting heat from exhaust gas and residual gas of the clinker production line to get steam to run the generator turbine and generate electricity to the factory's power grid to serve the production process, contributing to reducing product costs and protecting the environment. According to statistics, each year this system produces about 100 million MWh, providing up to 40% of the electricity consumed by Do Luong Cement Factory, saving production costs up to hundreds of billions of VND.

Mr. Vu Quang Trung - Manager of the Residual Heat Workshop of Do Luong Cement Factory said: The factory's residual heat generation system includes 2 generators, each with a capacity of 7MW and 4 boilers with a total steam generation capacity of 80 m3steam per hour. The operation of the 4 boilers is to use exhaust fans and excess air fans to draw excess hot air from the clinker production process through the boiler tubes to heat water, converting the water in the boiler from water to superheated steam.

|

| Activities in the operating room of Do Luong Cement Factory. Photo: NN |

Superheated steam has a pressure of about 1.3 Mpa and a temperature of about 3400C is led back to rotate the steam turbine. The turbine will pull the generator and generate electricity to the factory's power grid. The amount of hot air carrying dust when entering the boilers, the dust particles will change pressure and collide with the steam pipes, leading to loss of kinetic energy and falling into the collection funnel, dust from the collection funnels will be brought back into the production process. Thus, the exhaust gas and residual gas after passing through the residual gas power generation system will be clean of dust and cooled before being discharged into the environment. This is the best and most modern environmental protection solution in current cement production technology.

Mr. Vu Quang Trung added that when the excess gas power generation system is operating, steam will rise like white smoke, especially on days with high humidity in the air. Many people think it is dust, but in fact it is not, but steam rising from the turbine's condensate cooling tower.

|

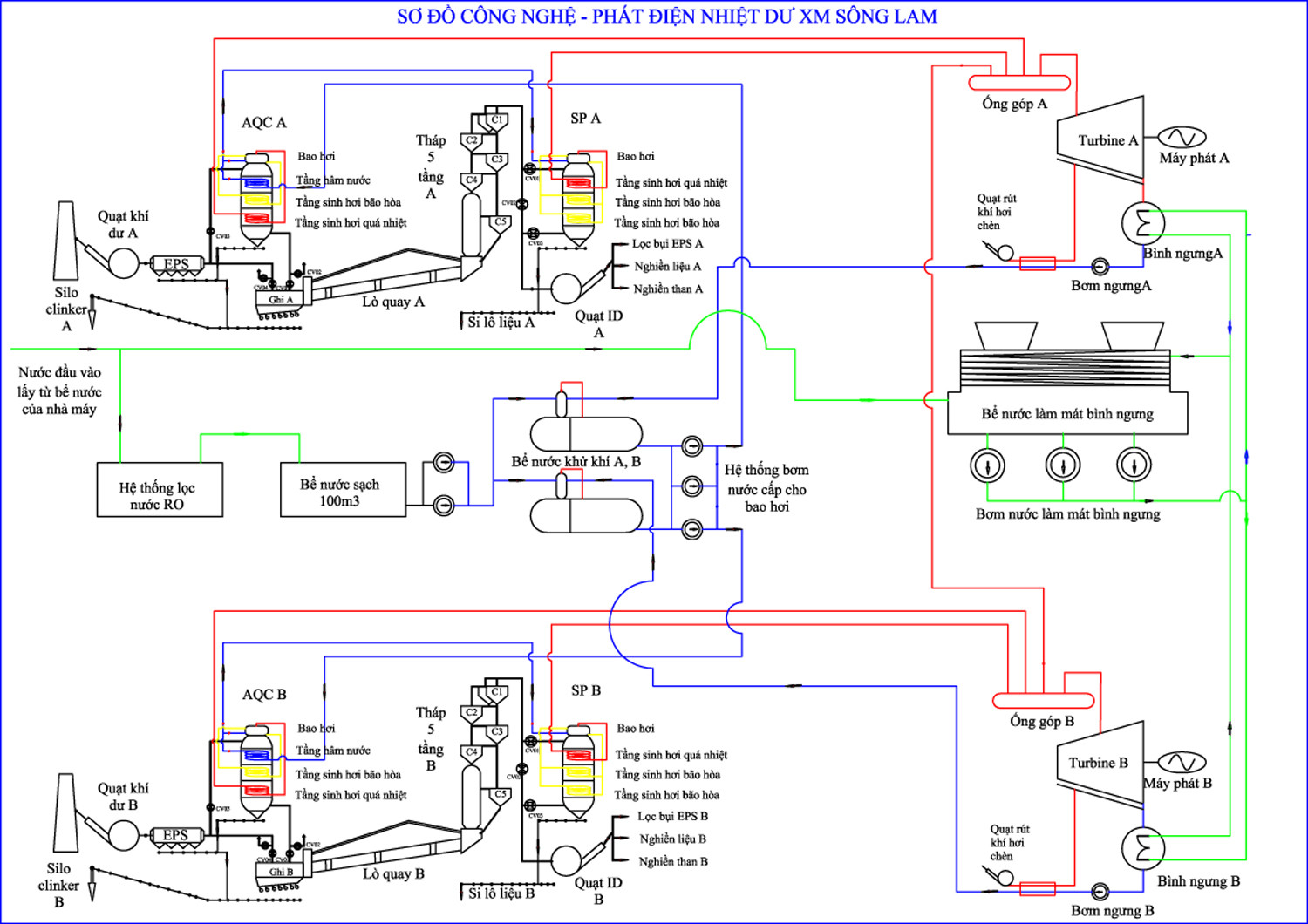

| Song Lam Cement Residual Heat Technology Diagram. |

Along with the residual gas thermal power generation system, Do Luong Cement Factory has a very modern electrostatic dust filter system with a dust filtering efficiency of up to 98.8%, so the amount of dust released into the environment is almost zero. The amount of dust recovered from the residual gas thermal power generation system and electrostatic dust filter is returned to the production process, helping the factory save production costs.

That is why Do Luong Cement Factory always pays attention to and directs the improvement of the efficiency of the electrostatic dust filter system and the excess gas thermal power generation system to both protect the environment and prevent resource loss, bringing revenue to the company.

|

| The application of the waste gas thermal power generation system and many other solutions has contributed to environmental protection in the Do Luong Cement Factory area. Photo: Contributor |